This website uses cookies to ensure you get the best experience on our website. Read more

What Is Jewelry Plating and It’s Types

What is Jewelry Plating?

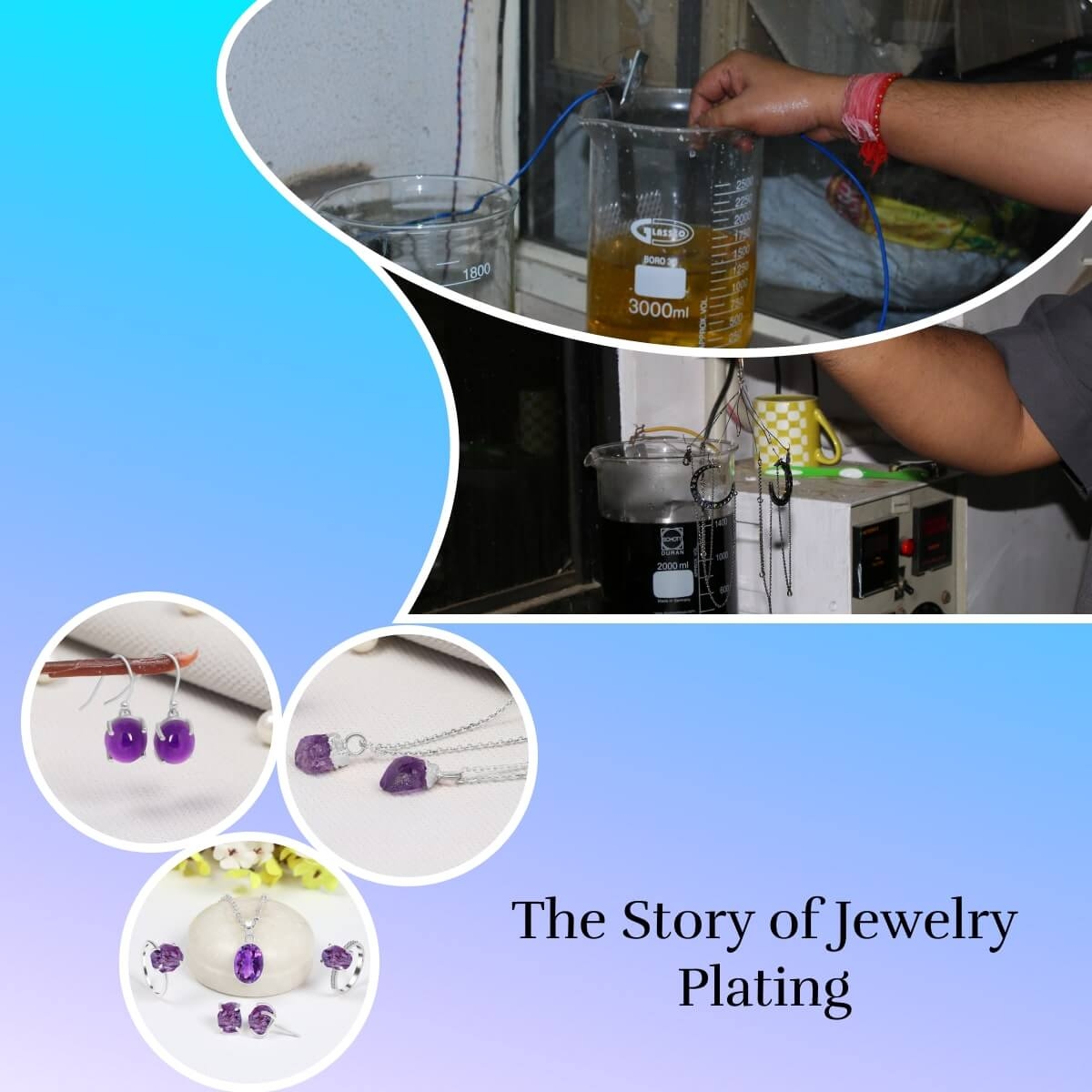

Jewelry plating, also called electroplating, is a surface treatment process where a thin layer of one metal is applied to the outer layer of another metal or composite. This process is used to improve the appearance, durability, and worth of jewelry items. By adding a layer of an alternate metal, jewelry manufacturers like ODM jewelry manufacturer & OEM jewelry manufacturer can accomplish different aesthetic effects, further improve corrosion resistance, and diminish the risk of allergenic reactions.

Historical Significance of Plating in Jewelry

The method of jewelry plating has a long history, following as far as possible back to old civilizations. Gold plating, specifically, has been utilized for millennia to create magnificent and visually striking jewelry pieces. Old Egyptians, Greeks, and Romans were known to use gold plating to enhance their jewelry, crowns, and religious antiques. Throughout time, various strategies and materials for plating have been created, prompting the changed scope of choices accessible to present-day jewelry designers.

Importance of Jewelry Plating

- Aesthetics: Plating permits designers to accomplish a wide range of colors and finishes that may not be possible with a single metal. This upgrades the visual allure of jewelry.

- Durability: The plating layer can work on the overall durability of the jewelry by giving a defensive boundary against wear and corrosion.

- Corrosion Resistance: Certain plating materials are exceptionally resistant to corrosion, making the jewelry suitable for regular wear.

- Allergenic Reaction Reduction: Plating can decrease the risk of skin irritation and allergic reactions that certain individuals might experience while wearing specific base metals.

- Increased Market Value: Plated jewelry items can frequently fetch higher prices in the market because of their enhanced appearance and perceived value.

Types of Jewelry Plating

There are specific types of jewelry plating, each offering amazing features regarding color, appearance, and properties. Here are some of the most common types:

Gold Plating

Gold plating is one of the most famous forms of jewelry plating. It includes applying a layer of gold onto the outer layer of a base metal or alloy. Gold plated jewelry can go from reasonable design pieces to high-end luxury items, depending upon the thickness and nature of the gold layer.

Silver Plating

Silver plating includes applying a layer of silver onto a base metal, such as brass or copper. This technique is used to make silver toned jewelry at a lower cost than solid silver items. Silver plated jewelry can be very lovely and is a more reasonable option in contrast to solid silver.

Rhodium Plating

Rhodium plating is principally utilized on white gold and silver jewelry. Rhodium is a glossy and profoundly reflective metal that can work on the whiteness and radiance of these metals. It likewise functions as a guarded layer against rust and corrosion.

Palladium Plating

Palladium plating is utilized to intensify the appearance and strength of jewelry items. Palladium is an exceptional and significant metal that offers a breathtaking white finish. It is, by and large, used on white gold jewelry to stay aware of its tone and prevent yellowing.

Platinum Plating

Platinum plating includes applying a dainty layer of platinum onto the outer layer of a base metal or alloy. This process is used to mimic the appearance of solid platinum jewelry while reducing costs. Platinum-plated designer jewelry or alphabet jewelry pieces are known for their durability and protection from discoloration.

Rose Gold Plating

Rose gold plating is a famous decision for making custom jewelry or gemstone jewelry with a warm, pinkish shade. It includes depositing a layer of rose gold onto a base metal or alloy. Rose gold plated jewelry pieces have a romantic and feminine appearance.

Black Rhodium Plating

Black rhodium plating is a specific procedure used to create black or dark grey jewelry pieces. It is mostly used to add contrast and depth to jewelry designs. Black rhodium plated jewelry can have a contemporary and tense look.

Methods of Jewelry Plating

Electroplating

Electroplating, also famous as electrodeposition, is the most widely used technique for jewelry plating. It includes submerging the jewelry piece in an electrolyte solution containing metal particles of the plating material. A direct current is then passed through the solution, causing the metal ions to migrate and bond to the surface of the jewelry item. Electroplating considers precise control over the thickness and quality of the plating layer.

Immersion Plating

Immersion plating is a less complex technique where the jewelry piece is submerged in a solution containing the plating material. Not at all like electroplating, there is no electrical flow associated with this process. Instead, the metal ions in the solution adhere to the outer layer of the jewelry through chemical reactions. Immersion plating is often used for small items and is less precise than electroplating.

Brush Plating

Brush plating, also known as selective plating, is a manual process that includes applying plating material to the explicit region of a jewelry item using a brush or applicator. This technique is also used for jewelry repairs and touch-ups.

PVD (Physical Vapor Deposition) Coating

PVD covering is a cutting-edge and high-level technique for jewelry plating that incorporates disintegrating the plating material and saving it onto the jewelry's surface in a vacuum chamber. This method makes a meager, uniform layer of plating material and is known for its strength and insurance from wear. PVD coatings can be applied in various tones and complete the process of making them extraordinarily adaptable.

The decision of plating technique relies upon factors like the type of jewelry, the desired finish, and the available equipment and skill. Electroplating and PVD coating are normally used for high-quality jewelry creation, while immersion plating and brush plating are more suitable for smaller-scale or repair work.

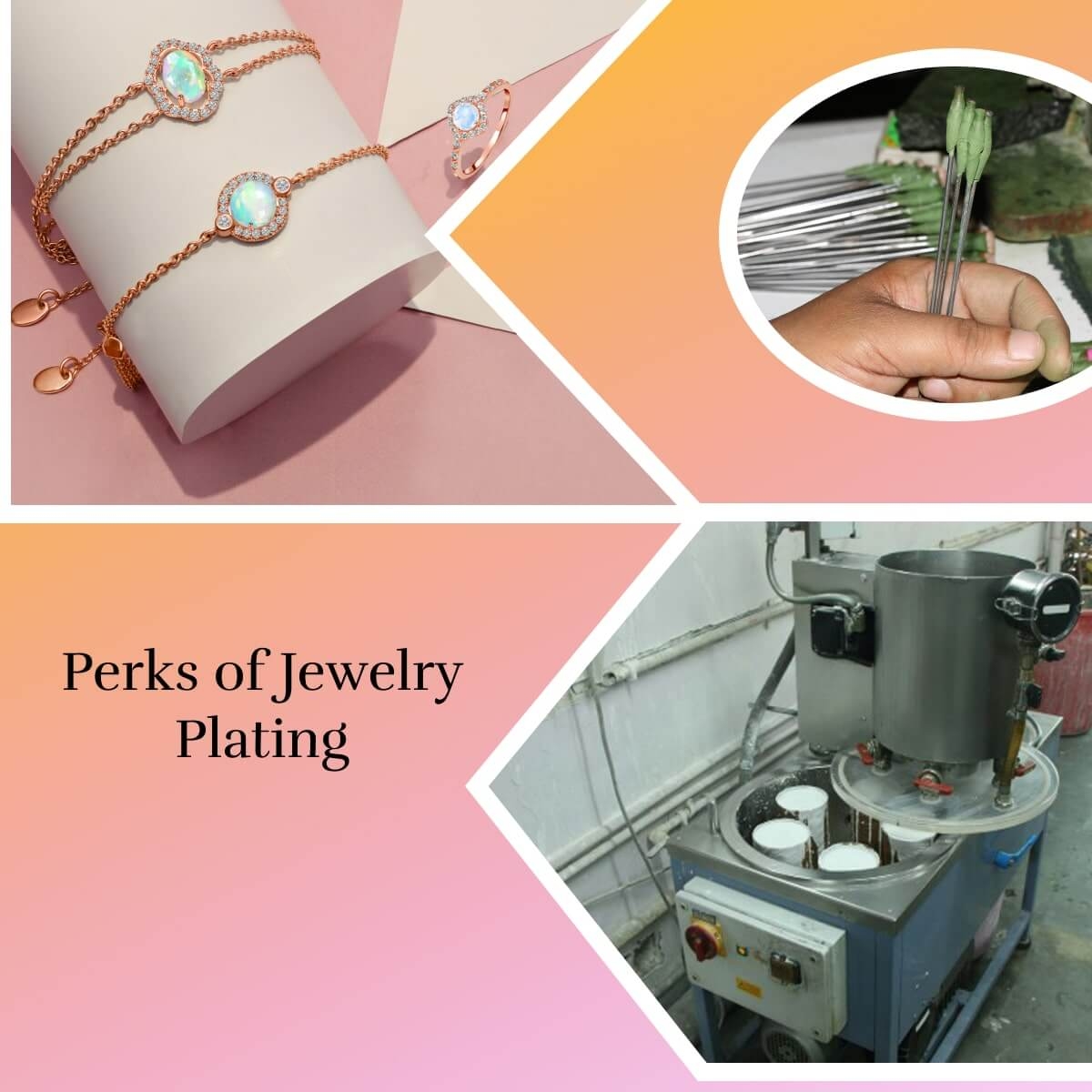

Benefits of Jewelry Plating

Aesthetics Enhancement

One of the essential reasons behind jewelry plating is to magnify the visual allure of jewelry items, whether it is handmade jewelry, casting jewelry, or any other kind of jewelry collection. Plating permits designers to accomplish many shades, finishes, and textures that can be challenging to accomplish with a single metal.

Improved Durability

Plating can essentially increase the durability of jewelry items. The plating layer functions as a protective layer and lessens the gamble of scratches, marks, and erosion. This is particularly huge for jewelry that is worn reliably and exposed to regular mileage.

Corrosion Resistance

Certain plating materials, like rhodium and palladium, offer magnificent corrosion resistance. When applied to jewelry made from less corrosion-resistant base metals, plating can prolong the lifespan of the piece and keep it looking pristine.

Allergenic Reaction Reduction

A few people might experience skin irritation or allergic reactions while wearing jewelry produced using specific base metals, like nickel. Plating jewelry with hypoallergenic materials like gold or rhodium can lessen the risk of such reactions, making the jewelry more comfortable to wear.

Considerations and Cautions

While jewelry plating offers many advantages, there are several important considerations and cautions to keep in mind:

Thickness of Plating

The thickness of the plating layer can fundamentally affect the durability and longevity of the jewelry item. Thicker plating is generally more durable but may also be more expensive. Thin or poorly applied plating can wear off over time, revealing the base metal beneath.

Wear and Tear

Even with plating, jewelry items can still experience wear and tear, especially if they are worn frequently or subjected to harsh conditions. It's crucial to handle plated jewelry with care and try not to open it to synthetic substances, abrasives, or outrageous temperatures that could harm the plating.

Maintenance

To preserve the appearance and life span of plated jewelry, regular maintenance is important. This might incorporate cleaning, polishing, and re-plating while the plating layer gives indications of wear. Different plating materials might require explicit care routines.

Conclusion

Jewelry plating is a captivating and fundamental part of the jewelry industry. It permits designers to change base metals into staggering bits of jewelry that show an upgraded feel, further developed durability, and protection from erosion. With different sorts of plating available, including gold, silver, and rhodium, and that's only the tip of the iceberg, the opportunities for making remarkable are practically boundless to pursue jewelry.

With everything taken into account, jewelry plating is a dynamic and creative field inside the jewelry business, and it continues with improvement promises to bring significantly thrilling open doors for wholesale gemstone jewelry manufacturers & suppliers from now on. Whether you're attracted to the brightness of gold plating, the radiant sheen of rhodium plating, or the tense charm of black rhodium plating, there's a world of plated jewelry at Rananjay Exports is always ready to be explored and appreciated.