This website uses cookies to ensure you get the best experience on our website. Read more

CAD Designing For The Jewelry Industry: A Case Study

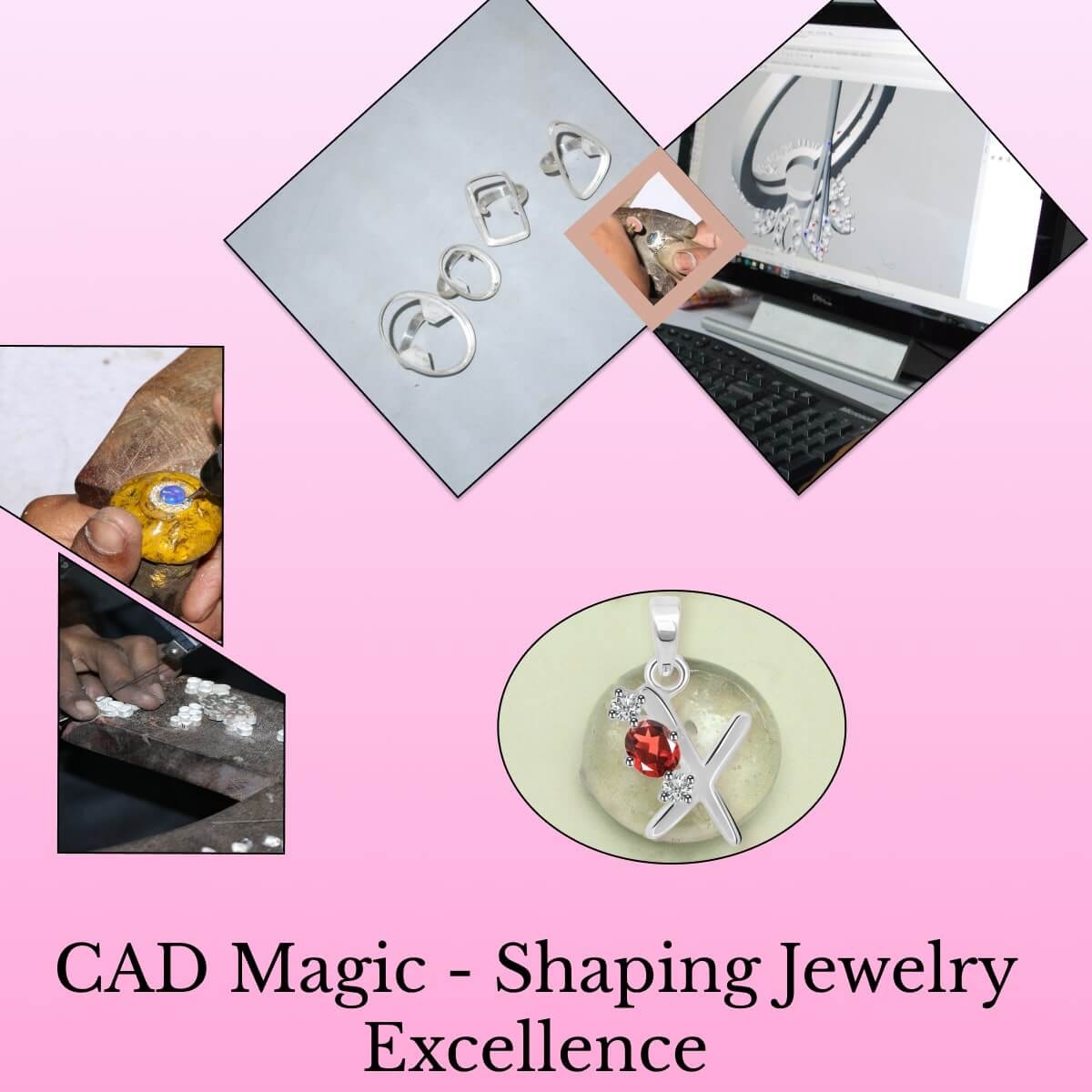

The jewelry industry has a long history of craftsmanship, creativity, and tradition. Since ancient times, jewelers have leveled up their abilities to make unimaginable and perfect pieces by hand. Even, with advancements in technology, the jewelry design process has advanced fundamentally. Computer-aided design (CAD) has emerged as an integral asset in the industry, empowering designers to make exact and perplexing jewelry designs with wonderful proficiency.

This case study explores the effect of CAD designing on the jewelry industry through a detailed examination of its advantages, challenges, and real-world case studies.

Benefits of CAD Designing in the Jewelry Industry

Precision and Accuracy: One of the main benefits of CAD designing in the jewelry industry is the accuracy and precision it offers. Traditional handcrafted jewelry designs might have slight differences because of human error, yet CAD takes into consideration amazing balance and precise measurements. Designers can make unique patterns and complex calculations effortlessly, guaranteeing that the final product meets the highest quality standards.

Time Efficiency: CAD essentially decreases the time expected to make jewelry designs. What could require days or weeks to create by hand can be achieved in a fraction of the time with CAD software. This time, productivity speeds up the design process as well as permits jewelry manufacturers to bring new products for sale to the public all the more rapidly, fulfilling consumer demands and staying competitive.

Design Iteration and Customization: CAD empowers designers to handily make changes and iterate on their designs. This adaptability is particularly important while making customized jewelry pieces for individual customers. Designers can quickly change the elements, like size, shape, and stone setting, to meet a client's particular preferences, guaranteeing consumer satisfaction.

Cost Reduction: By smoothing out the design and creation process, CAD helps reduce costs in several ways. In the first place, it limits material waste by improving designs for the effective utilization of valuable metals and gemstones. Second, it eliminates the requirement for costly hand-cutting and molding processes. Third, it decreases the risk of errors and rework, saving both time and money.

Complex Geometry and 3D Visualization: CAD designing permits jewelry designers to explore many-sided and complex mathematical shapes that would be challenging or difficult to create by hand. Furthermore, 3D visualization devices enable designers and customers to see a realistic representation of the final piece, assisting with guaranteeing design satisfaction before creation starts.

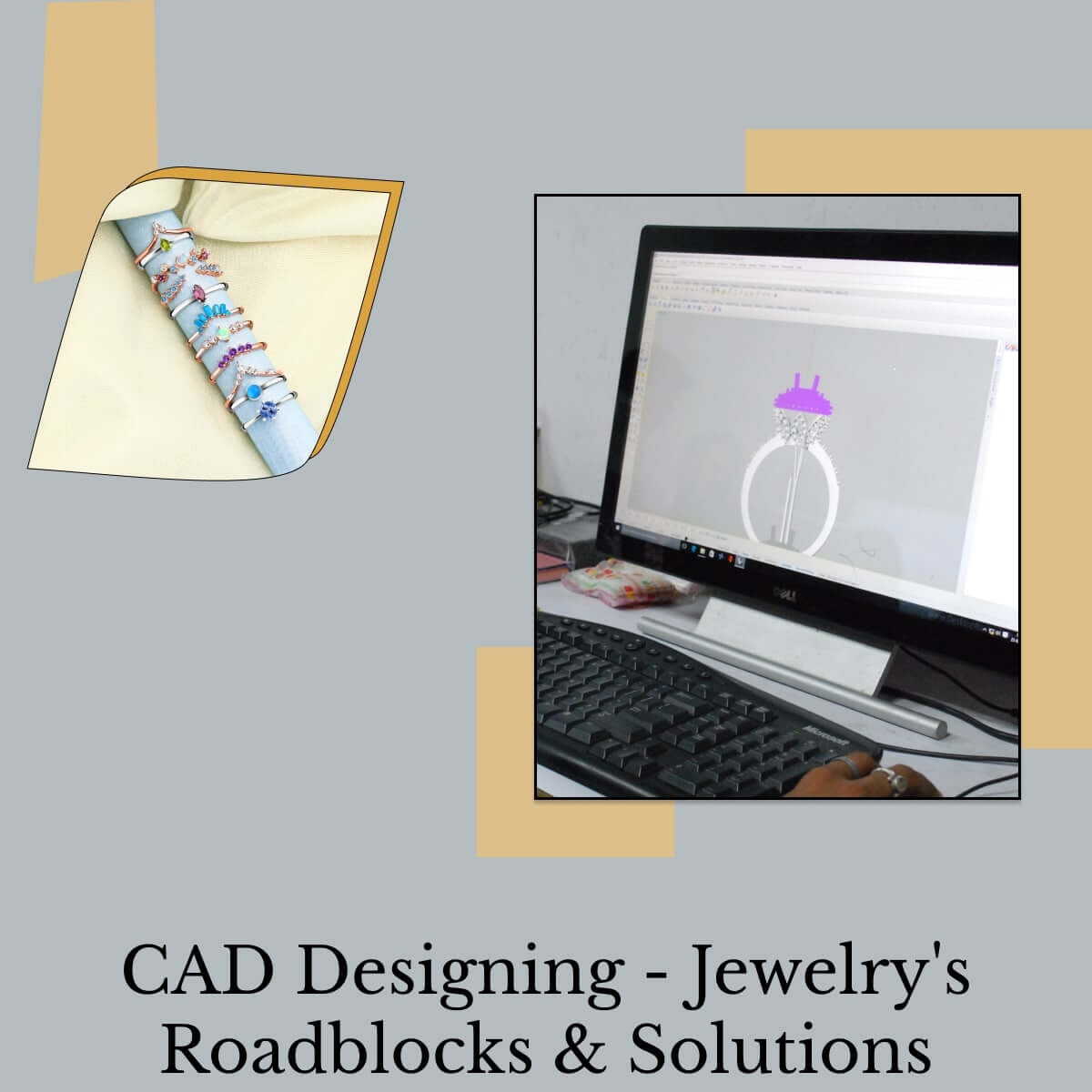

Challenges in Implementing CAD Designing in the Jewelry Industry

Initial Investment: The adoption of CAD technology requires a significant initial investment in software, hardware, and employee training. Small-scale jewelry businesses may find it challenging to justify these upfront costs, but the long-term benefits often outweigh the initial financial outlay.

Learning Curve: CAD software can be complex, and may expect designers to really go through extensive training to use it effectively. This expectation to absorb information can dial back the progress from traditional methods to CAD, and a few designers might be resistant to change.

Design Theft and Intellectual Property Concerns: With the digital idea of CAD documents, there is an increased risk of design theft or intellectual property infringement. Designers and manufacturers need to execute vigorous safety efforts to safeguard their digital assets.

Design Authenticity: A few idealists contend that handcrafted jewelry holds a unique authenticity and sentimental value that CAD-designed pieces lack. While CAD offers accuracy and consistency, it may lack the emotional connection that handmade jewelry can evoke.

Case Study: Transforming a Traditional Jewelry Factory with CAD

To delineate the effect of CAD designing in the jewelry industry, we should look at the journey of a traditional jewelry factory, Rananjay Exports, a Wholesale Gemstone Jewelry Manufacturer and supplier," which chose to embrace CAD technology.

Background:

Rananjay Exports specializes in crafting captivating collections of alphabet jewelry, custom jewelry, gemstone jewelry, handmade jewelry, and so on, and is known for its quality and craftsmanship. However, they faced increasing competition from larger jewelry manufacturers using CAD technology to produce designs faster and at a lower cost.

Challenges:

Staying Competitive: Rananjay Exports realized that they expected to embrace CAD Designing to remain competitive in the market and cater to younger, well-informed customers.

Transitioning Skill Set: The skilled craftsmen at Rananjay Exports were specialists in traditional jewelry crafting yet had little experience in CAD software.

Implementation:

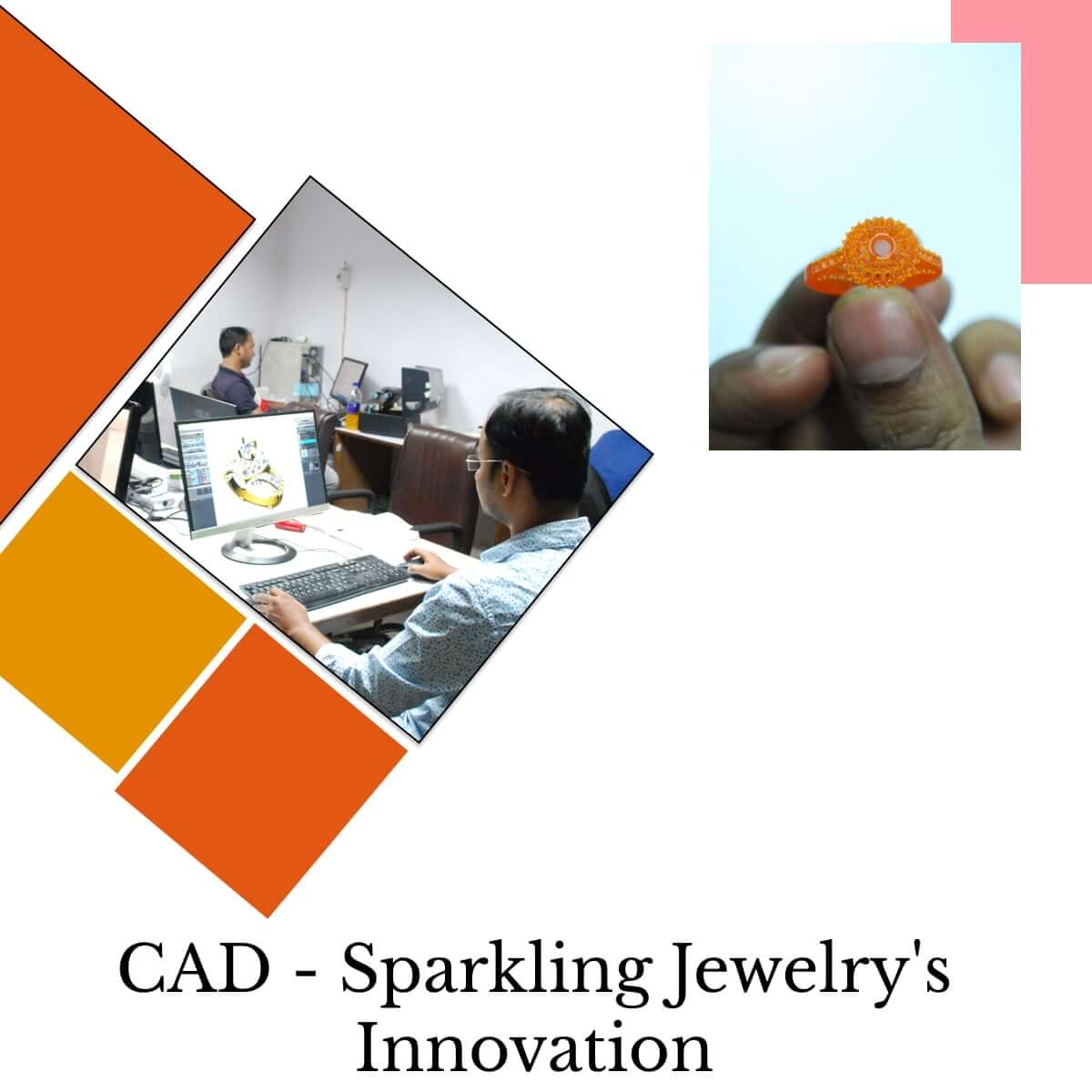

Investment in CAD Technology: Rananjay Exports made the initial investment in CAD programming and hardware, guaranteeing they had the latest tools to support their change.

Training and Up Skilling: The company provided comprehensive training to its artisans, enabling them to learn CAD software proficiently.

Design Integration: Rananjay Exports started incorporating CAD into its design process. At first, they utilized CAD to make detailed design models and later to produce final pieces.

Results:

Improved Efficiency: With CAD, Rananjay Exports fundamentally decreased the time expected to make complex jewelry designs. This proficiency permitted them to take on additional orders and fulfill clients' demands promptly.

Customization: CAD empowered Rananjay Exports to offer a more extensive scope of customization choices to their clients. They could now effectively change designs to meet specific client demands.

Cost Reduction: The decrease in material waste and the elimination of hand-carving and molding processes led to cost savings for the company.

Competitive Advantage: Rananjay Exports was now able to compete effectively by offering both traditional handcrafted pieces and CAD-designed jewelry.

Final Thought

CAD designing has reformed the jewelry industry by offering accuracy, effectiveness, and customization capabilities. As technology keeps on advancing, CAD will likely play an even more significant role in shaping the future of the jewelry industry. Rananjay Exports, a leading name in the industry, has successfully harnessed CAD design techniques to reform different parts of its operations, from casting jewelry to gemstone polishing. This innovation not only streamlines production but also enhances precision, ensuring the creation of exquisite designer jewelry.

Moreover, Rananjay Exports' commitment to quality is exemplified through meticulous processes, for example, jewelry plating, intensive quality checks, and a dedicated stone department for gemstone selection and setting. The collaboration between CAD technology and high-quality craftsmanship has empowered Rananjay Exports to lay down a good foundation for itself as both an ODM jewelry manufacturer and OEM jewelry manufacturer, taking care of different customers.