This website uses cookies to ensure you get the best experience on our website. Read more

The Lost Wax Process - Important Historical Techniques

The Lost Wax Process, additionally popular as a speculation casting process, is an old and complex procedure that has been utilized by specialists and experts for centuries. This strategy of projecting metal articles is indicated by its extraordinary accuracy and potential to catch convoluted subtleties. Its set of experiences traverses over 5,000 years, making it quite possibly the main strategy throughout the entire existence of workmanship and metallurgy.

In old times, the lost wax process has been utilized to plan wonderful sculptures, jewelry, and, surprisingly, useful items like apparatuses and weaponry. This persevering strategy has risen above time and keeps on being applicable in present-day craftsmanship and industry. This process has advanced and adjusted throughout the long term, from its earliest known use in ancient civilizations to its continued importance in the 21st century. In this blog, we will investigate the captivating history of the Lost Wax Process, find out about its different purposes, and analyze its getting through heritage in both artistic and industrial worlds.

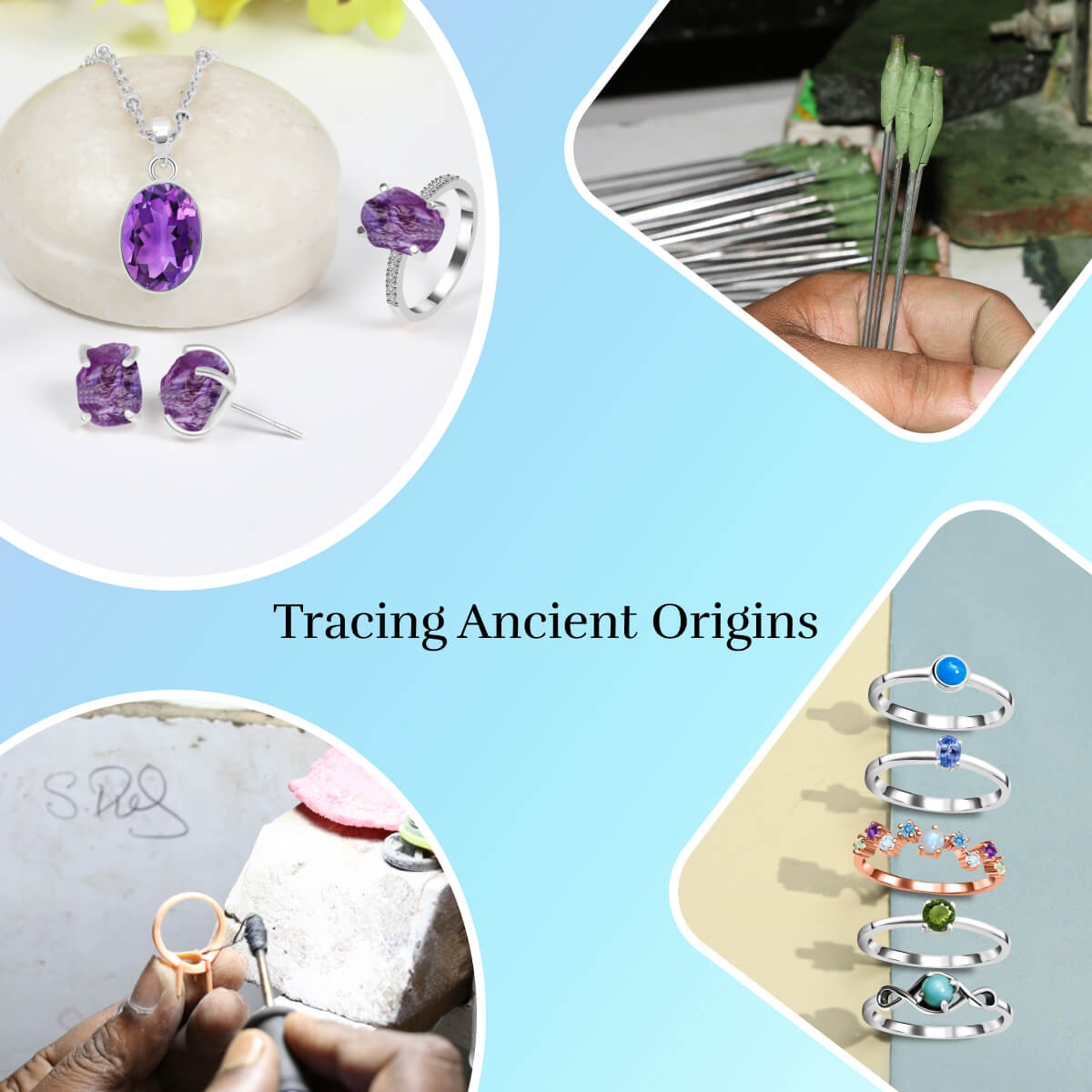

Ancient Beginnings (c. 3500 BCE - 500 CE):

The origins of the Lost Wax Process can be traced back to old civilizations like Mesopotamia, Egypt, and the Indus Valley. These early metalworkers utilized the procedure to make beautiful jewelry, ornaments, and little figurines.

Wax Modeling: In its initial stage, craftsmen would shape an ideal item from beeswax or different kinds of wax. They would cut complicated details into the wax to accomplish the desired pattern.

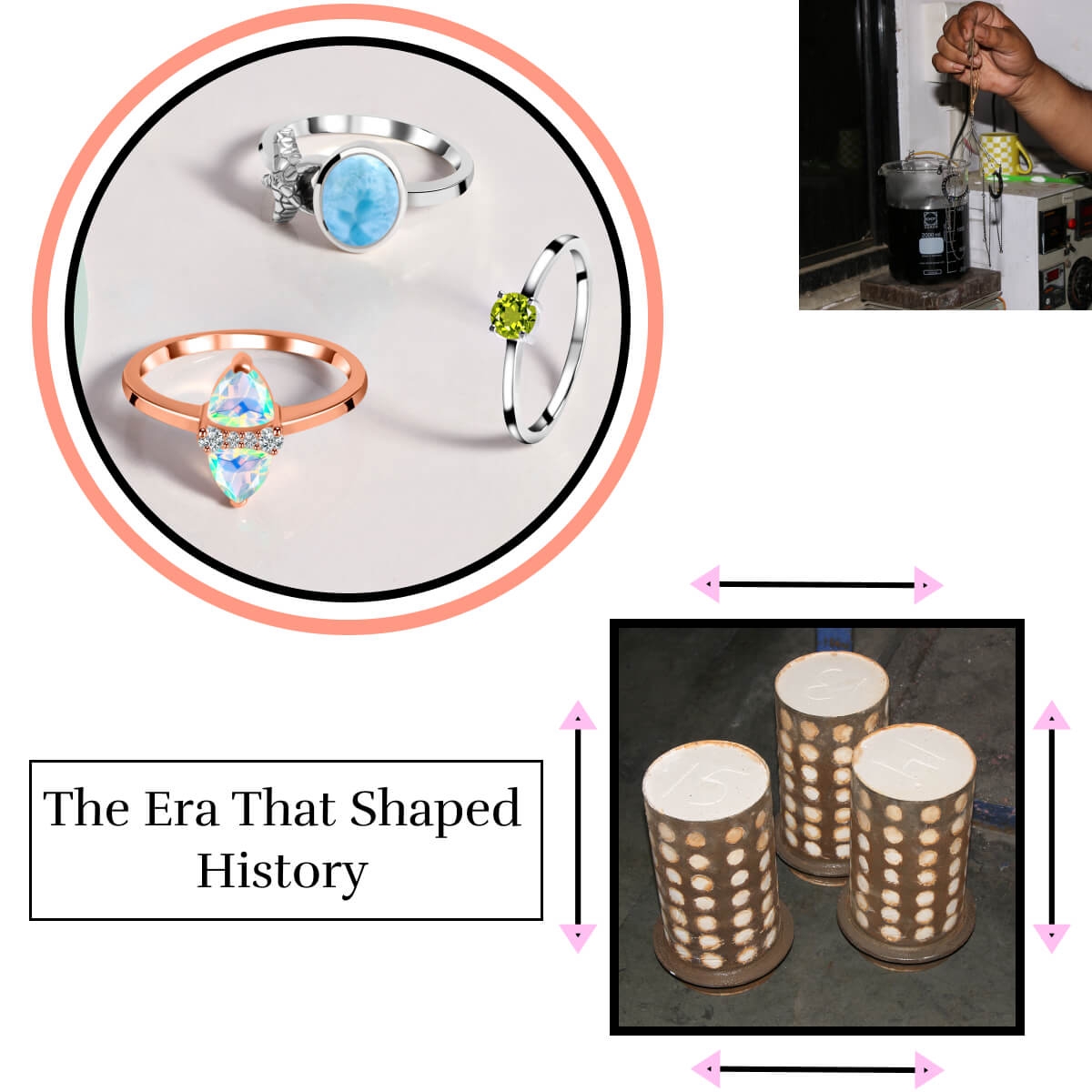

Investment: In the next stage, the wax model was then covered with a layer of clay or other heat-resistant materials. This created a mold around the wax, leaving a cavity that would eventually house the molten metal.

Burnout: The mold was warmed, making the wax melt and run out, leaving an empty cavity inside the mold.

Metal Casting: Liquid metal, frequently bronze or metal, was filled in the empty mold, taking the shape of the original wax model.

Demolding: When the metal had cooled and hardened, the clay model was split away, uncovering the final metal object. The last finishing details were applied, like cleaning, polishing, and assembly if needed.

Classical and Medieval Periods (500 CE - 1500 CE):

During this time, the Lost Wax Process kept on being utilized for creative and religious purposes, creating models religious icons, and enhancing components for structures and reinforcement.

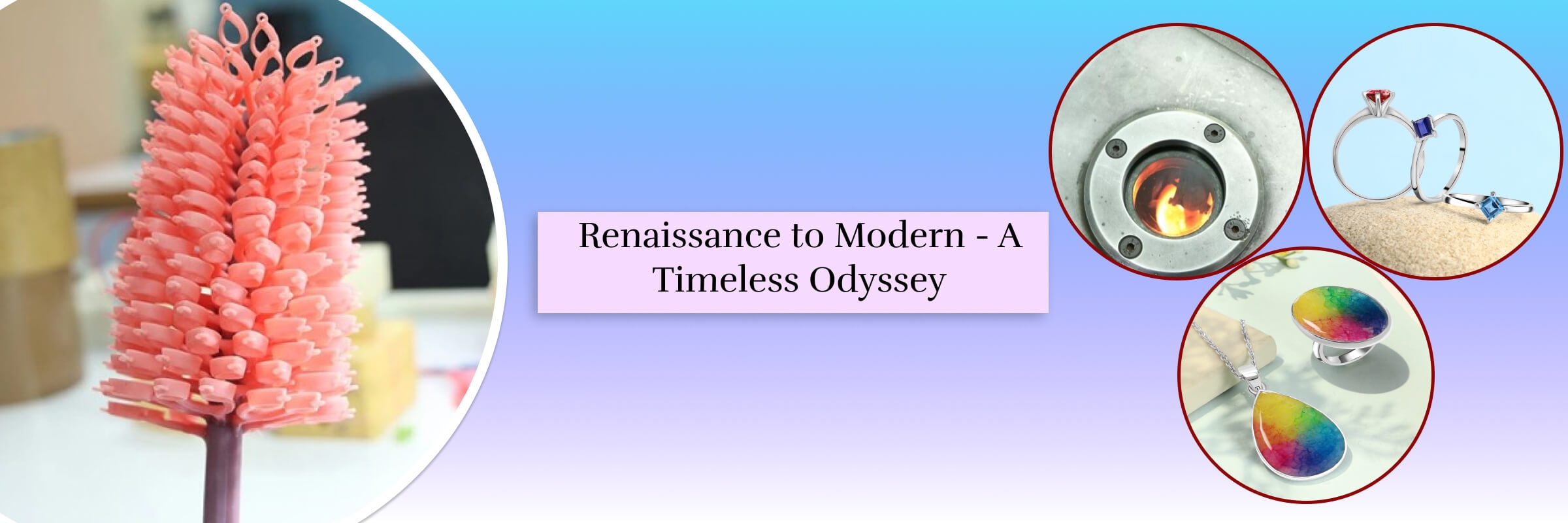

Renaissance and Beyond (15th - 18th Century):

The Renaissance saw a resurgence in interest in old-style art and craftsmanship. The Lost Wax Process was embraced by specialists and artists like Donatello and Benvenuto Cellini to make exact and point-by-point bronze models.

Industrial Revolution (18th - 19th Century):

The approach of the Modern Insurgency acquainted automation with the Lost Wax Process, making it more proficient and accessible. Developments incorporated the utilization of elastic molds and divergent casting machines to smooth out the creations.

20th Century Advancements:

The 20th century brought further technological advancements to the Lost Wax Process:

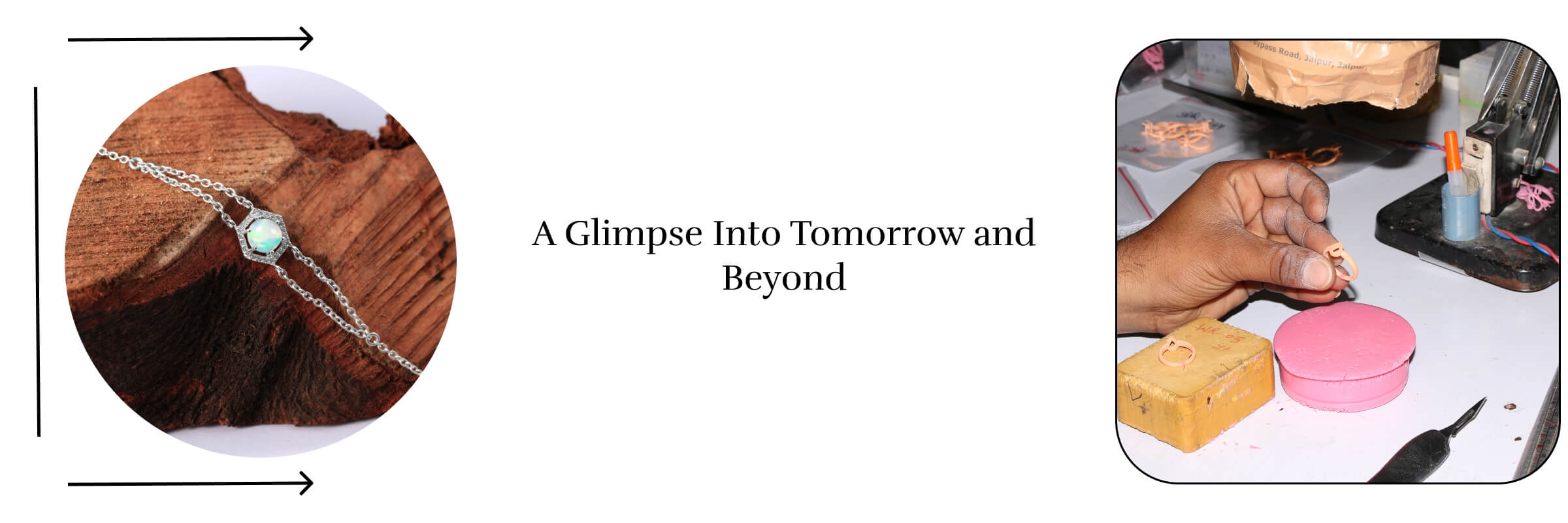

Rubber Molds: Rubber turned into a well-known material for making molds because of its flexibility and sturdiness. Craftsmen and producers could make multiple copies of a single wax model.

Ceramic Shell Casting: This variety of investment casting utilizes a ceramic shell rather than clay for mold making, taking into consideration more significant details and smoother finishes.

3D Printing: In the late 20th century and mid 21st century, the Lost Wax Process began consolidating 3D printing technology. Craftsmen and architects could make unimaginable wax models utilizing computer-aided design (CAD) software and 3D printers, smoothing out the modeling stage.

21st Century and Beyond:

The Lost Wax Process continues to evolve and adapt to modern needs and technologies:

Advanced Materials: New alloys and composite materials are being utilized for casting, offering improved properties for a wide range of applications, including aerospace, clinical gadgets, and car components.

Digital Modeling: The utilization of computerized modeling and reenactment programming has become boundless, considering exact command over the casting process and reducing waste.

Additive Manufacturing: At times, 3D printing has changed from making wax models to straightforwardly creating metal parts through different added substance manufacturing procedures.

Quality Control: Modern methods, for example, non-destructive testing and X-ray assessment, guarantee the greatest quality and integrity of cast parts.

Sustainability: Sustainable practices, remembering reusing and decreasing energy utilization for casting processes, are turning out to be progressively significant in the 21st century.

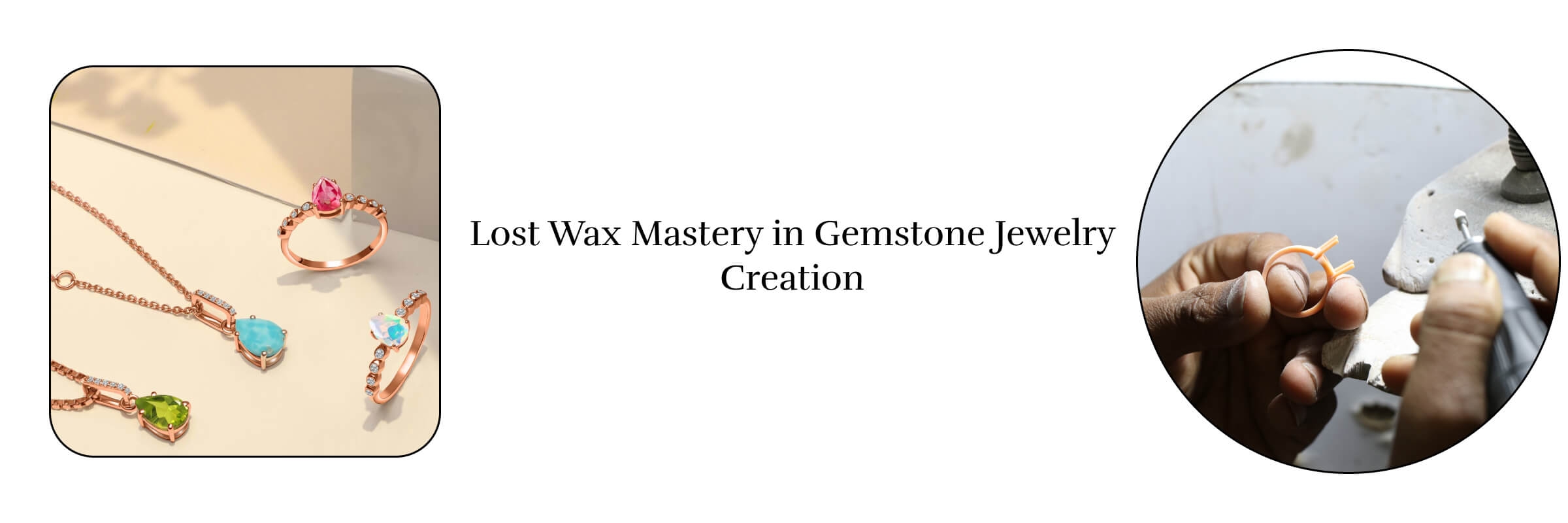

The Lost Wax Process: An Integral Part of Wholesale Gemstone Jewelry Manufacturing

In the world of wholesale gemstone jewelry manufacturing, the Lost Wax Process is a well-established technique that has stood the test of time. This complicated and interesting strategy is at the core of making perfect bits of Alphabet Jewelry, Casting jewelry, Custom jewelry, Handmade jewelry, and designer jewelry. With an emphasis on Gemstone jewelry, this method has been instrumental in changing raw gemstones into mesmerizing wearable art.

Gemstone Selection and Preparation

Prior to plunging into the Lost Wax Process, the gemstones utilized in wholesale jewelry manufacturing go through a meticulous process. This incorporates Caming and Gemstone polishing to improve their magnificence and clarity. The craftsmen in the Stone department skillfully shape and facet gemstones flawlessly, guaranteeing they supplement the imagined jewelry design.

CAD Designing and Customization

The Lost Wax Process flawlessly supplements the universe of Custom jewelry. Because of cutting-edge (CAD) designing technology, clients can team up with artists to make exceptional pieces that reflect their own style. Whether it's consolidating explicit gemstones like emerald, sapphire, or precious stones or making amazing shapes and settings, the Lost Wax Process allows for limitless possibilities in gemstone jewelry customization.

Precision Casting and Jewelry Plating

When the wax model is idealized, it goes through precision casting. This step is essential to keeping up with the complex details of the jewelry design. The molten metal is carefully filled in the mold, taking the state of the wax model inside. After cooling and solidifying, the jewelry piece emerges with remarkable precision. Following casting, the jewelry might go through Jewelry Plating processes to accomplish the ideal completion, whether it's brilliant gold or smooth silver. This step adds the last bit of polish to the Gemstone jewelry.

Quality Assurance and Stone Setting

In wholesale gemstone jewelry manufacturing, quality is important. Rigid jewelry Quality Check are directed to guarantee each piece fulfills the highest standards of craftsmanship. This includes inspecting stone settings, metal quality, and overall design. The Lost Wax Process plays an essential role in Stone Setting. Gemstones are safely and perfectly settled inside their settings, enhancing their brightness and allure. Whether it's a moonstone-studded necklace or a larimar-enhanced ring, the Lost Wax Process guarantees that gemstones are exhibited in the most charming way.

Collaboration with ODM and OEM Jewelry Manufacturers

The Lost Wax Process is adaptable, making it appropriate for both Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM). ODM jewelry manufacturers can use this method to rejuvenate their unique designs, while OEM jewelry manufacturers can create pieces to meet specific brand requirements.

Final Thought

The Lost Wax Process has a rich history going back millennia, developing from a manual specialty to a highly complex and mechanically progressed strategy. Its flexibility and versatility keep on making it a significant method in different industries, from craftsmanship and sculpture to aerospace and manufacturing, as we move further into the 21st century. The Lost Wax Process is a key procedure in wholesale gemstone jewelry manufacturing.

Its capacity to transform raw gemstones into flawless collections of gemstone jewelry exhibits its persevering significance in the industry. With an emphasis on Gemstone Jewelry, this deep-rooted technique, combined with modern innovation and craftsmanship, proceeds to charm and spellbind jewelry enthusiasts around the world.