This website uses cookies to ensure you get the best experience on our website. Read more

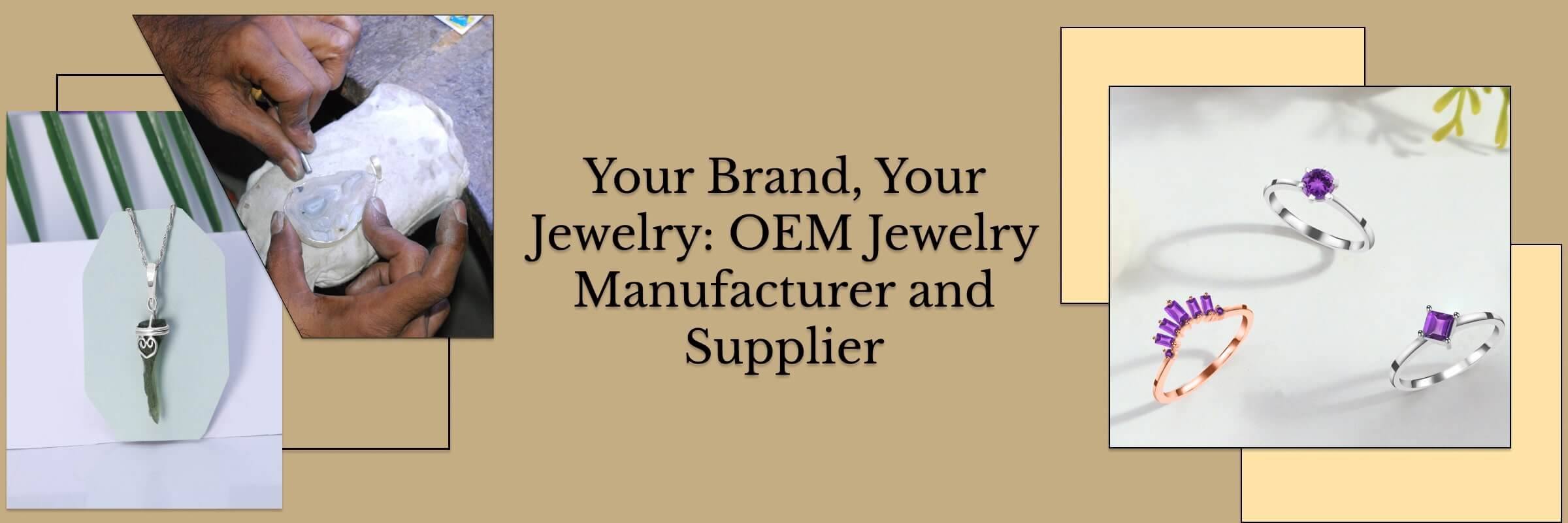

OEM Jewelry Manufacturer and Supplier - Custom Creations For Your Brand

Jewelry is a recognizable symbol of identity, culture, and style in the ever-changing world of fashion and luxury. And Original Equipment Manufacturer (OEM) jewelry manufacturers and suppliers have a significant impact on the dynamics of the market in the always-changing jewelry industry environment. OEM describes the process through which one firm creates goods or components that a different company subsequently uses to incorporate into its own finished products. OEM jewelry manufacturers and suppliers are the backbone of the jewelry business in general, providing essential components, expertise, and innovation to jewelry brands all around the world.

Partnering with an ODM Jewelry Manufacturer and Supplier & Original Equipment Manufacturer (OEM) jewelry manufacturer and supplier may be the key to unlocking the door of customization, innovation, and quality for companies looking to make their mark in this complicated and sparkling industry. The partnership offers a voyage through the arts of gemstone production and crafting, from conception to the finished masterpiece, with a concentration on wholesale gemstone jewelry, custom jewelry, casting jewelry, handmade jewelry, designer jewelry, and gemstone jewelry.

Understanding OEM Jewelry Manufacturing and Supply

OEM jewelry manufacturing involves producing jewelry components or even complete pieces on behalf of other jewelry manufacturers. These elements could include chains, gemstones, settings, clasps, and more. The OEM jewelry manufacturer operates as a silent partner, collaborating with jewelry brands to bring their designs to life while remaining behind the scenes. On the other side, OEM jewelry suppliers are experts in supplying raw materials such as precious metals, gemstones, pearls, and other essential components to OEM manufacturers. These suppliers make sure there is a consistent supply of high-quality materials, which enables manufacturers to produce beautiful items.

OEM jewelry manufacturers and suppliers operate behind the scenes, yet their influence on the industry is undeniable. Through cost-effective production, specialized expertise, and innovative collaboration, they enable jewelry brands to bring their designs to life efficiently and competitively. While challenges exist, the benefits of OEM partnerships continue to reshape the jewelry market, contributing to its vibrant diversity and constant evolution. As the industry continues to adapt to changing consumer preferences and market dynamics, the role of OEM jewelry manufacturing and supply remains integral to its success.

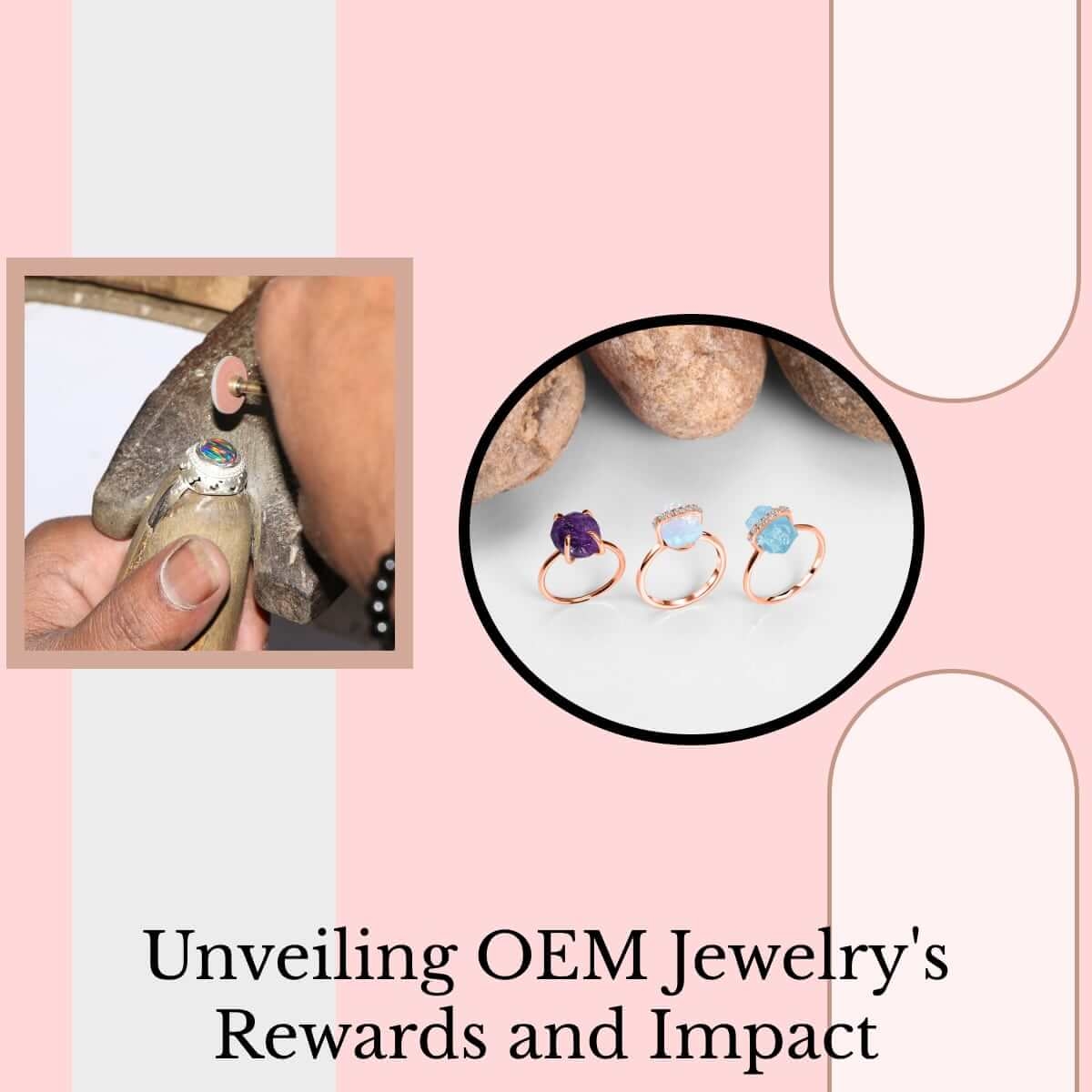

Significance and Benefits Of OEM Jewelry Manufacturing

- Cost-Efficiency: Cost-effectiveness is one of the main advantages of creating OEM jewelry. Jewelry businesses may concentrate their efforts on design, marketing, and other essential areas while lowering manufacturing costs by outsourcing specific components or processes.

- Expertise and Specialization: OEM jewelry manufacturers and suppliers often have particular training and experience. With this knowledge, high-quality accessories and components that satisfy exacting industry requirements may be produced.

- Time Savings: Collaborating with OEM partners can significantly reduce the time required for jewelry production. Manufacturers can quickly access necessary components, allowing them to bring designs to market faster.

- Innovation and Creativity: OEM partners often bring new perspectives and innovative techniques to the table. This collaboration can lead to the creation of unique and trend-setting jewelry pieces.

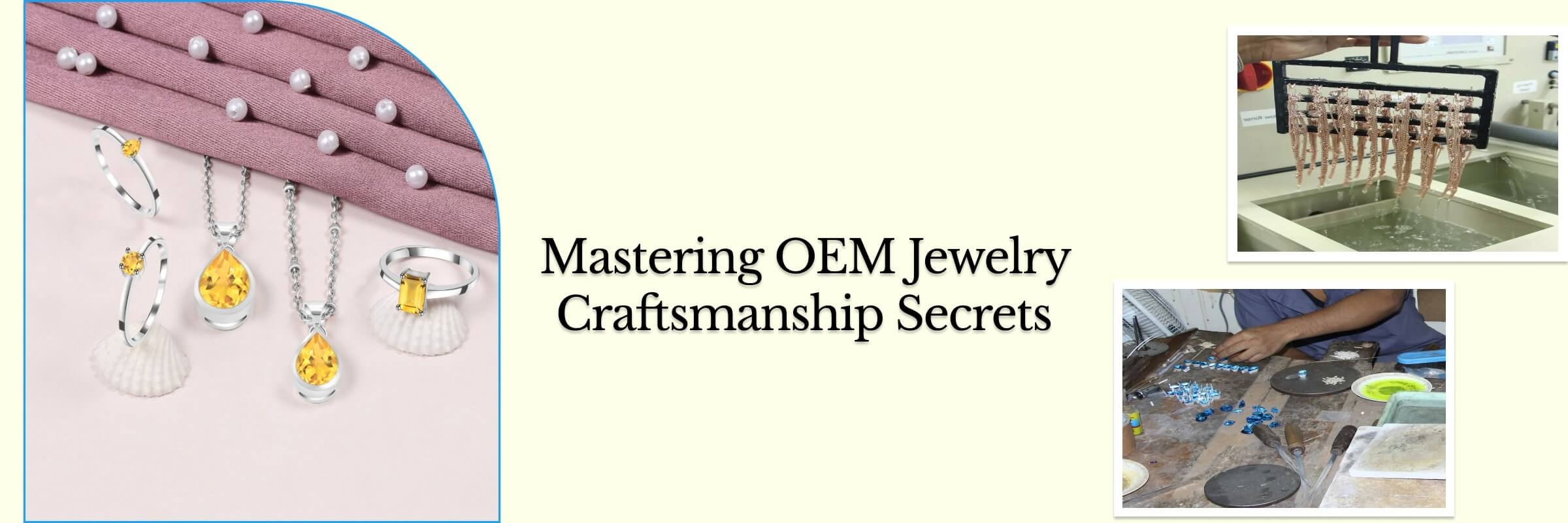

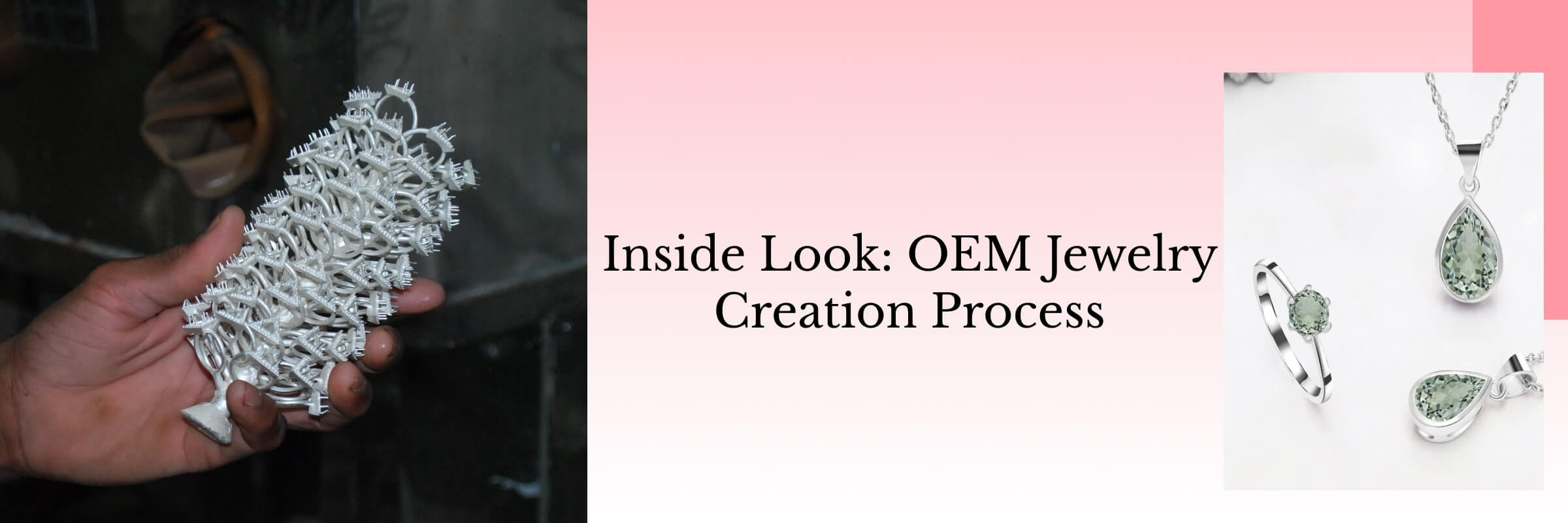

OEM Jewelry Manufacturing Process

The Process Of OEM Jewelry Manufacturing Involves Several Stages:

- Design and Conceptualization: Jewelry companies provide the OEM manufacturer with their design ideas and requirements. This stage is essential to making sure the finished product aligns with the brand's vision.

- Material Selection: If the OEM supplier is involved, the manufacturer selects the appropriate materials, such as precious metals and gemstones, based on the brand's requirements.

- Component Production: The jewelry components are made by the OEM manufacturer in accordance with the given requirements. This could include casting, stone setting, polishing, and other processes.

- Quality Control: Stringent quality checks are carried out to ensure that the components meet the required standards for aesthetics, durability, and safety.

- Assembling and Finishing: The final jewelry pieces are created by assembling the components after they are prepared. Additional procedures like soldering, engraving, and detailing can be necessary.

- Packaging and Delivery: The finished pieces are packaged and delivered to the brand, ready for retail or distribution.

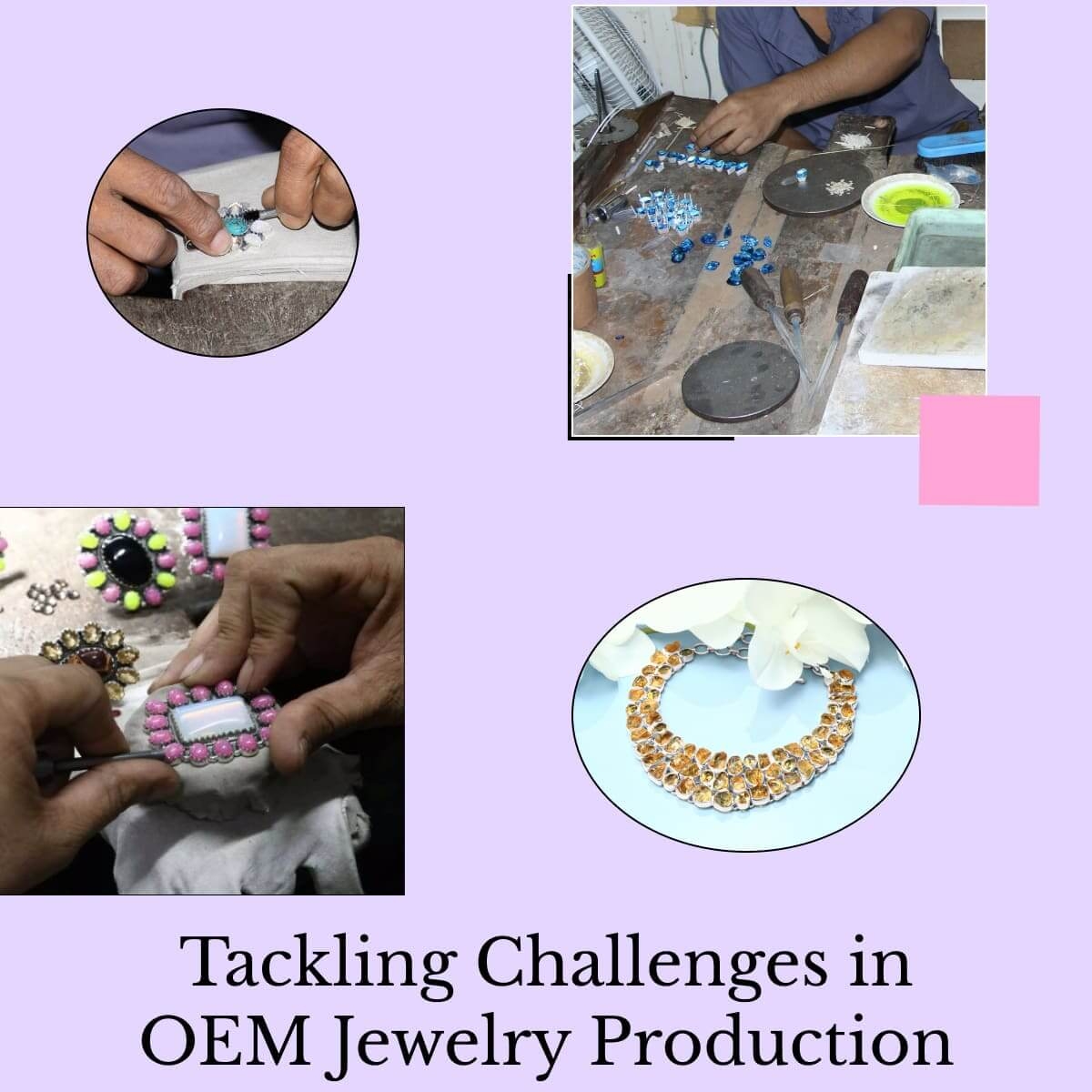

Challenges Faced By OEM Jewelry Manufacturers & Suppliers

While OEM jewelry manufacturing offers numerous benefits, it also comes with its own set of challenges:

- Quality Control: It might take a lot of work to guarantee consistent quality across a large number of components. The brand and the OEM partner must work closely together to maintain quality requirements.

- Communication: Effective communication between the brand and the manufacturer is crucial to prevent misunderstandings and guarantee that the finished product fulfills expectations.

- Intellectual Property Concerns: Protecting design ideas and intellectual property may be challenging when working with OEM partners. To overcome these issues, clear agreements and contracts are required.

- Dependency Risks: Brands that heavily rely on OEM partners may face risks if the manufacturer experiences disruptions in production or quality issues.

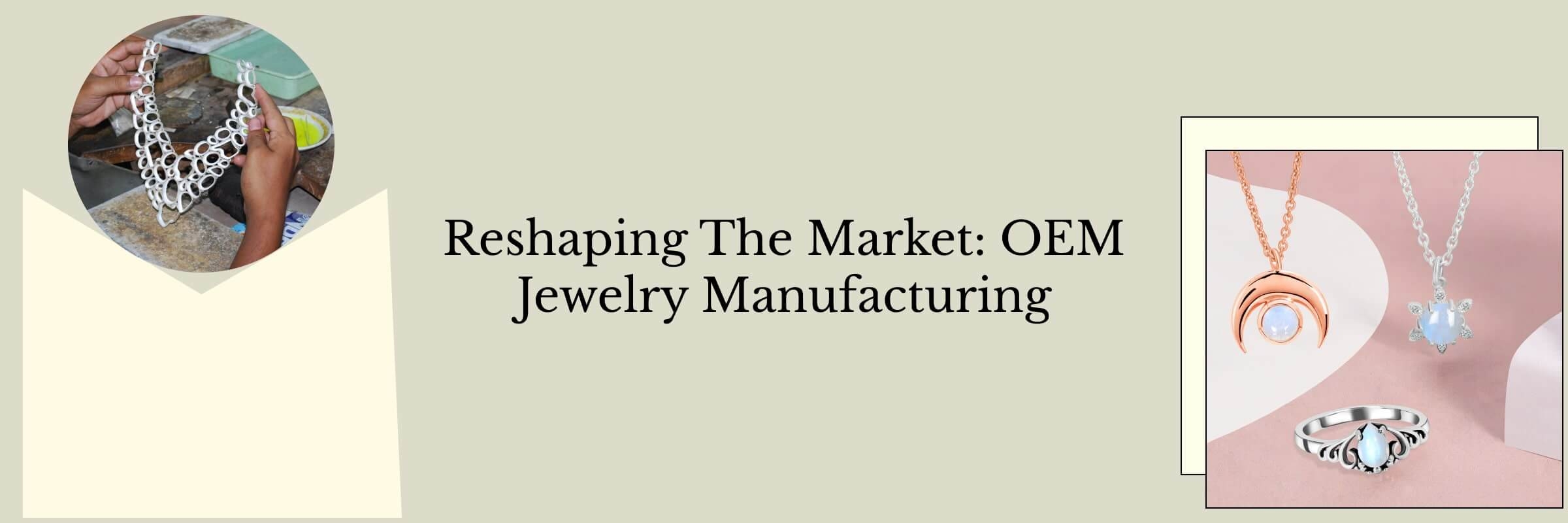

OEM Jewelry Manufacturing's Impact On The Market

The presence of OEM jewelry manufacturers and suppliers has a significant impact on the broader jewelry market:

- Diversity and Innovation: OEM collaborations support innovation and creativity by enabling a wide variety of jewelry designs and styles on the market.

- Accessibility: Without the necessity for sizeable internal production facilities, small and new jewelry manufacturers may get high-quality components by using OEM manufacturing.

- Market Dynamics: The cost-effectiveness of OEM production may have an impact on pricing policies within the sector, impacting both the high-end and more moderately priced jewelry sectors.

- Globalization: The globalization of the jewelry industry is facilitated by OEM partnerships, allowing brands to collaborate with manufacturers and suppliers from different parts of the world.

Rananjay Exports - Your Premium OEM Jewelry Manufacturer and Supplier

Discover the essence of elegance with Rananjay Exports, your premium OEM jewelry manufacturer and supplier. Elevate your brand's uniqueness through our custom creations that epitomize luxury and style. With Rananjay Exports, experience a seamless journey from concept to a masterpiece as we transform your visions into exquisite jewelry lines.

Our expert craftsmanship, exceptional quality, and attention to detail ensure that every piece reflects your brand's identity. Partner with us to create jewelry that resonates with your clientele, setting you apart in the market. Because at Rananjay Exports, we don’t just create jewelry; we craft captivating stories of luxury and allure.