This website uses cookies to ensure you get the best experience on our website. Read more

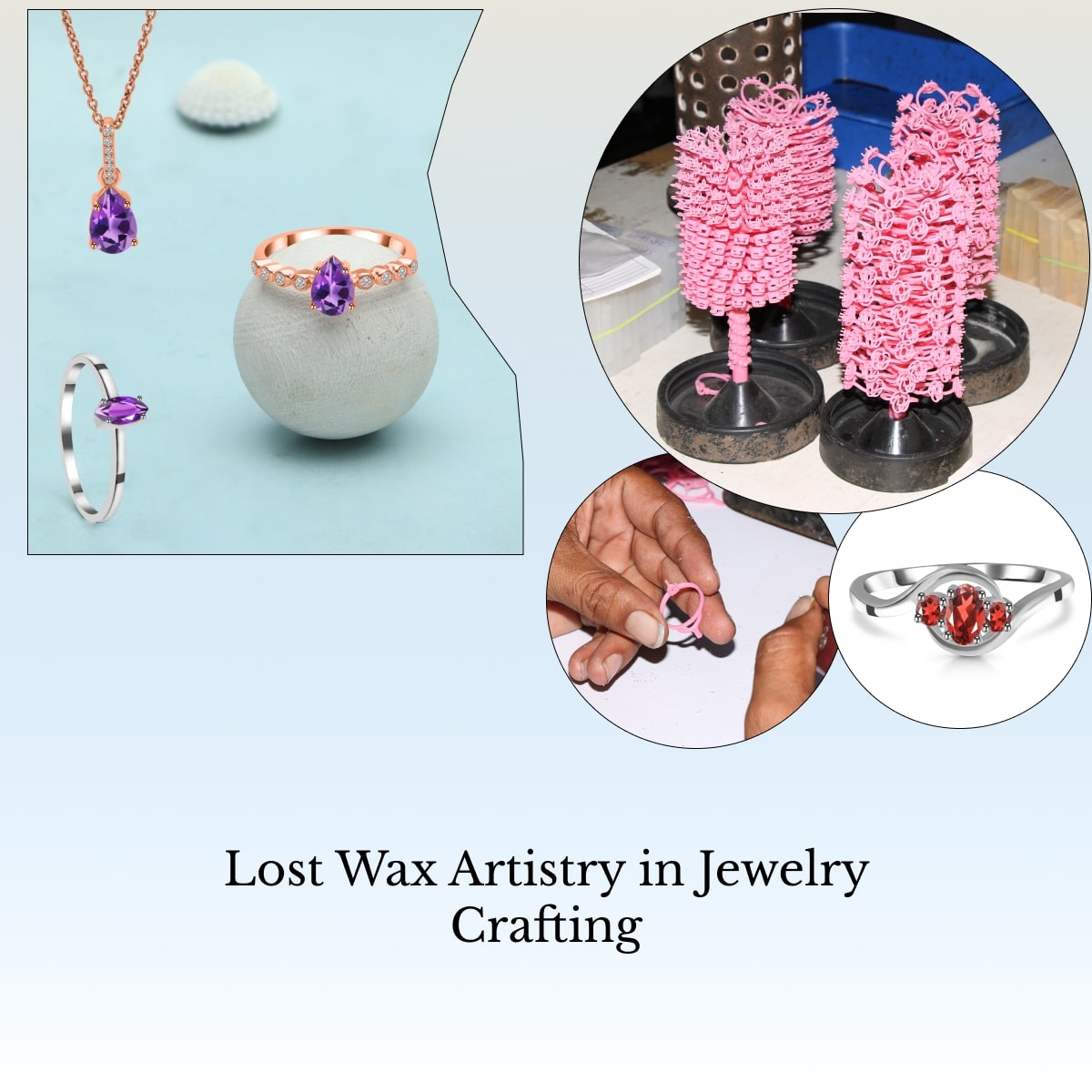

Lost Wax Casting: The Art of Creating Jewelry with Precision and Detail

Introduction

Lost wax casting is the process of creating objects, such as casting jewelry, from simple to complex, in a variety of metals like bronze, brass, silver, 925 sterling silver, or gold, by casting an original model or pattern. Lost wax casting is perhaps one of the oldest known metal-forming techniques. Dating back to about 6,000 years, it is still a widely used technique employed in the production of jewelry, and in fields such as dentistry and art. The industrial form of lost wax casting, which is also known as investment casting, is a common way in case you want to create metal parts with precision, which is required a lot in fields such as manufacturing and engineering.

Although casting jewelry made through the process of lost wax casting has been traditionally associated with artisanal handcraft, creators of the 21st century can now transform the lost wax casting process with 3D printing and digital design. For what? Well, to simplify the workflow, save time, and lower costs, and when looking at the bigger picture, to reshape the entire process.

The History of Lost Wax Casting

We are not exaggerating the fact, but historians believe that lost wax casting and the production of casting jewelry are as old as the civilization itself. Beautiful artifacts such as sculptures, ornaments scepters, and furniture made through lost wax casting have been discovered in distant places such as the Indus Valley, Vietnam, Israel, Nigeria, and Nicaragua. The oldest known object created via lost wax casting is an amulet created by the Indus Valley society, which in and of itself is 6,000 years old. Thus, it's not wrong to assume that casting jewelry has been used by mankind for at least the past 6,000 years.

For centuries, the lost wax casting process has been used in the production of relief textiles and sculptural ornaments. In 18th-century Europe, lost wax casting began to be replaced by piece molding. But, then in the 19th century, parts of the process were adapted for investment casting so as to meet the needs of the growing industry. You would be amazed to know that lost wax casting has uses other than making casting jewelry, such as in dentistry. Lost wax methods are widely used in dentistry to create gold crowns, onlays, and inlays.

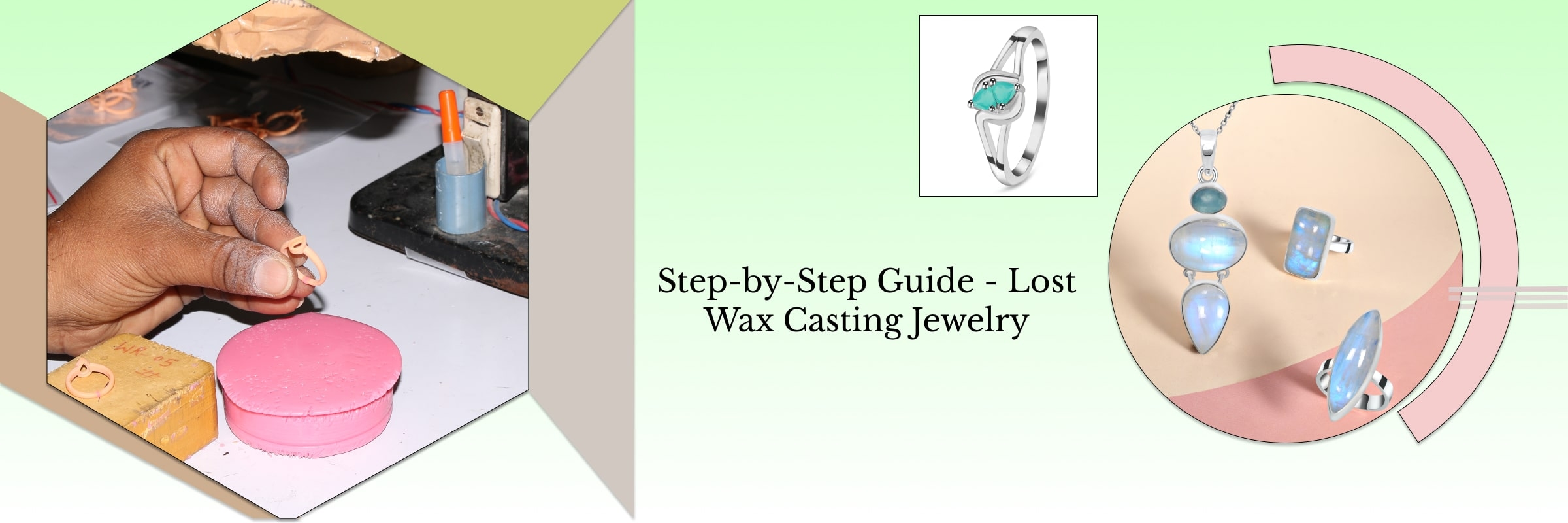

The Lost-Wax Casting Process for Creating Casting Jewelry: A Step-by-Step Guide

The process of lost wax casting can differ from industry to industry, and the application it has in that particular industry, however, it generally consists of the following steps. The parts that are cast can be made from the wax model itself, which is known as the direct method of creating casting jewelry, or they can be made from replicas of the original wax model, called the indirect method of creating casting jewelry. The direct method jumps from step one to step four.

Step 1: Model-Making

In step 1, the artist carves a design purely out of wax. The complexity and size of the wax model are dependent on the wax carver’s skills, and the ability of his casting equipment.

Step 2: Creating a Mold

Once the model is carved, the caster then casts this model and polishes the casting in order to produce a “master” pattern. The master model is then used to make a wax mold purely out of rubber, which is then heated and vulcanized in the master casting so as to make a flexible wax mold.

Step 3: Producing Wax Patterns

The molten wax is either injected or poured into the rubber mold. This process can be repeated over and over again to produce copies of the original design.

Step 4: Assembling the Wax Patterns

Once the wax copies are made, spruces are added to these wax copies and they are connected in order to create a tree-like structure. This tree-like structure provides paths for the molten wax to flow out and it also enables the molten metal to later fill the cavity by creating a proper pathway.

Step 5: Applying investment materials

In this step, the wax tree is either put into a flask surrounded by liquid investment plaster, or it is dipped into a slurry of silica which is inside a flask.

Step 6: Burnout

The investment material inside the flask is left for drying. Once the investment material has dried out, the flask is put upside down into a kiln and then heated. Through this process, the wax melts away, leaving a negative cavity in the shape of the original model.

Step 7: Pouring

After the wax melts out, the investment mold, which is the leftover, is further heated in the kiln so as to reduce the temperature difference between the molten metal (such as 925 sterling silver, gold, etc.) and investment mold. Once the temperature difference is reduced, the metal is melted and poured through the use of gravity or vacuum pressure so as to pull the metal into the cavity.

Step 8: Devesting

After the molten metal cools down, the investment mold is doused in water. This dissolves the refractory plaster and releases casting in its rough form. Post this, the spruces are cut off and recycled whereas the casted parts are cleaned up and polished so as to remove the signs of the casting process.

Step 9: Finishing

The cleaned casted parts, generally made up of precious metals, are ground, filed, sandblasted, and machined so as to achieve surface finish and final geometry. Sometimes, the cast parts are also heat-treated so as to enhance the mechanical properties of the precious metal, but this is not considered a necessity.

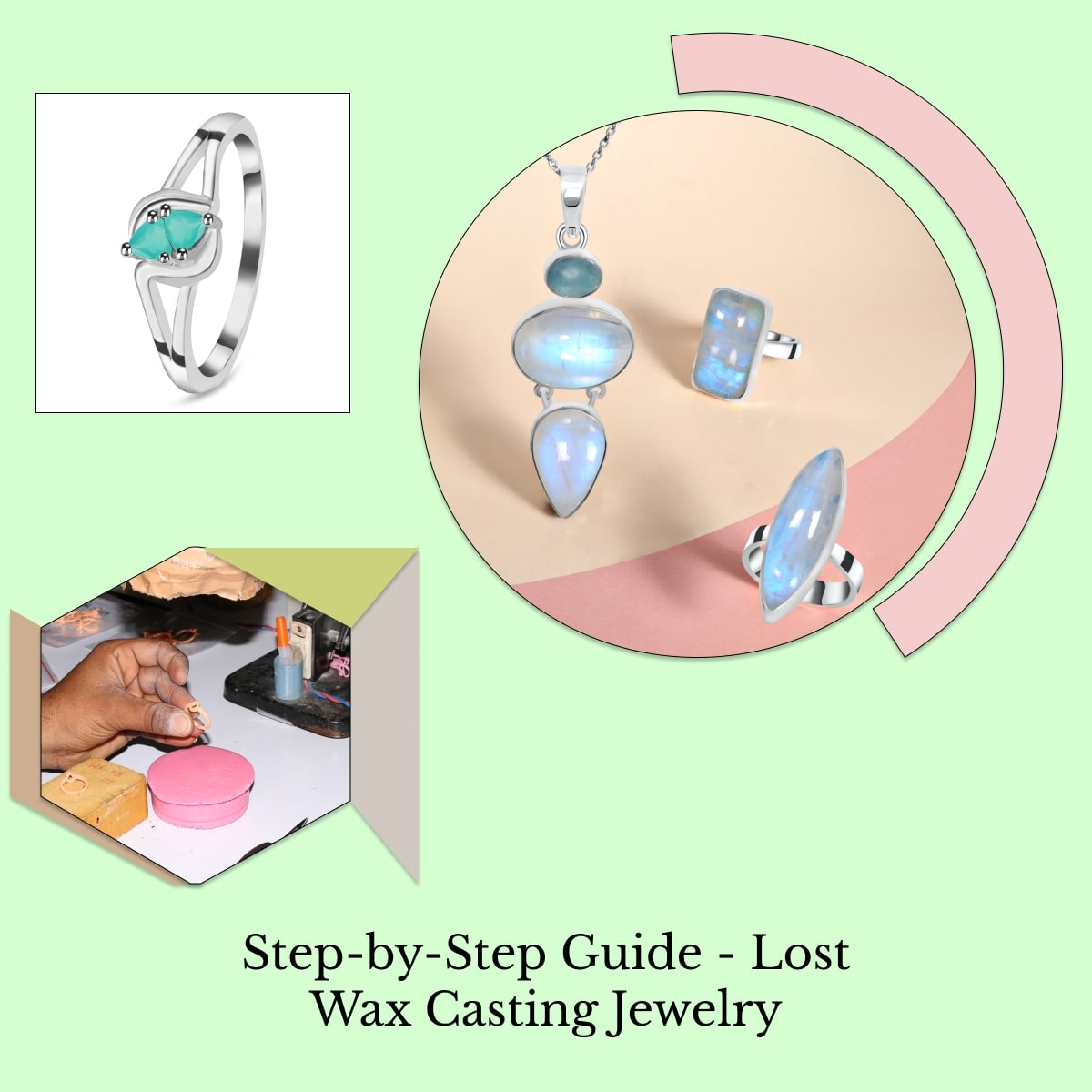

Lost-Wax Casting in the 21st Century: How Digital Design and 3D Printing Augment the Casting Process

In today’s times, 3D printing and digital software tools augment the lost wax casting process, making the entire process of creating casting jewelry much easier, while also being more advantageous in the complete manufacturing process.

Through the help of the digital workflow, designers use CAD software tools such as Rhino and AutoCAD to create designs digitally. These digital designs are then used to produce 3D-printed patterns using a high-resolution 3D printer. Post the burnout of positive pattern, the process has the same structure as the traditional investment casting.

Only because of these digital techniques, the need for time-intensive manual labor that goes into carving a model purely out of wax is reduced greatly. Through the 3D printer, the design itself is easy to preserve, modify, and recreate when needed.

Conclusion

The evolution of the process of lost wax casting with digital tools is living proof of the concept that technology does not alienate us from the past. Provided that this technique is employed correctly, it can produce high-quality parts at scale – from bespoke custom jewelry to mass-produced casting jewelry that you see in the catalog of various wholesale gemstone jewelry manufacturers and suppliers. One of the best benefits that you can have from casting jewelry is, design freedom and a remarkable new degree of production efficiency.

By the way, are you in search of a wholesale gemstone jewelry manufacturer and supplier who could supply you with casting jewelry? If yes, then browse through the official website of Rananjay Exports: India’s most renowned wholesale gemstone jewelry manufacturer that deals in a wide range of casting jewelry, such as alphabet jewelry, moon magic jewelry, chakra jewelry, zodiac sign jewelry, birthstone jewelry, and plain silver jewelry. Not only do they sell casting jewelry, but they also sell custom jewelry, handmade jewelry, designer jewelry, and gemstone jewelry in over 250+ gemstones – all of which are natural and ethically sourced. So, rather than waiting, browse Rananjay Exports now, and order your desired jewelry.