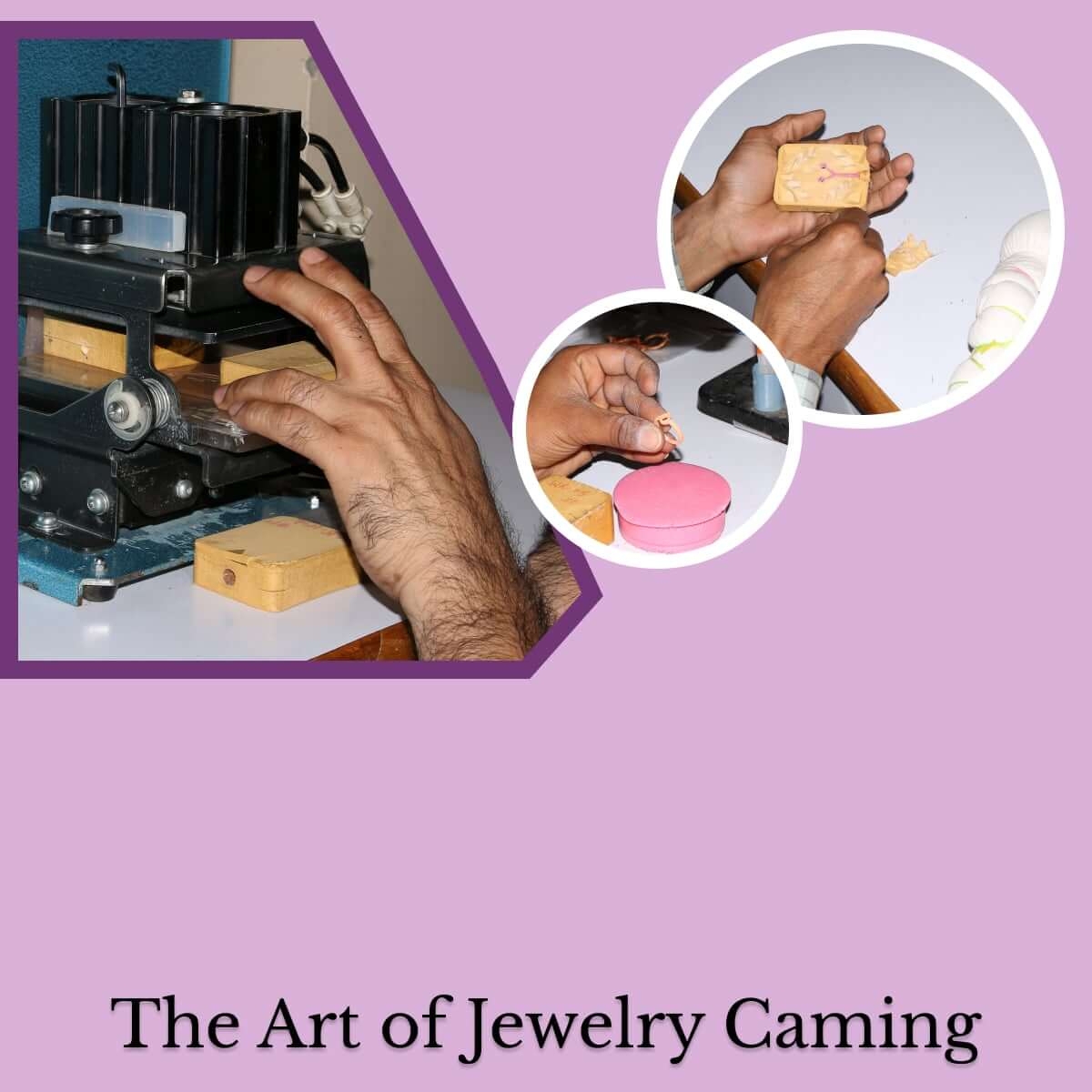

The world of jewelry manufacturing is a stunning process that consolidates imagination, craftsmanship, and precise design. One of the essential part of jewelry creation is the caming process, a series of complex steps that transform raw materials into mesmerizing pieces of jewelry. It includes a few key parts, each adding to the overall transformation of gemstones into wearable masterpieces. In this ultimate guide, we will learn deeply about the caming process, exploring each feature from designing to gemstone polishing, featuring its importance in the world of Wholesale Gemstone Jewelry Manufacturing. Whether you are a jewelry enthusiast, a Wholesale Gemstone Jewelry Manufacturer and Supplier, or essentially inquisitive about the complex universe of jewelry creation, this guide is your ultimate resource.

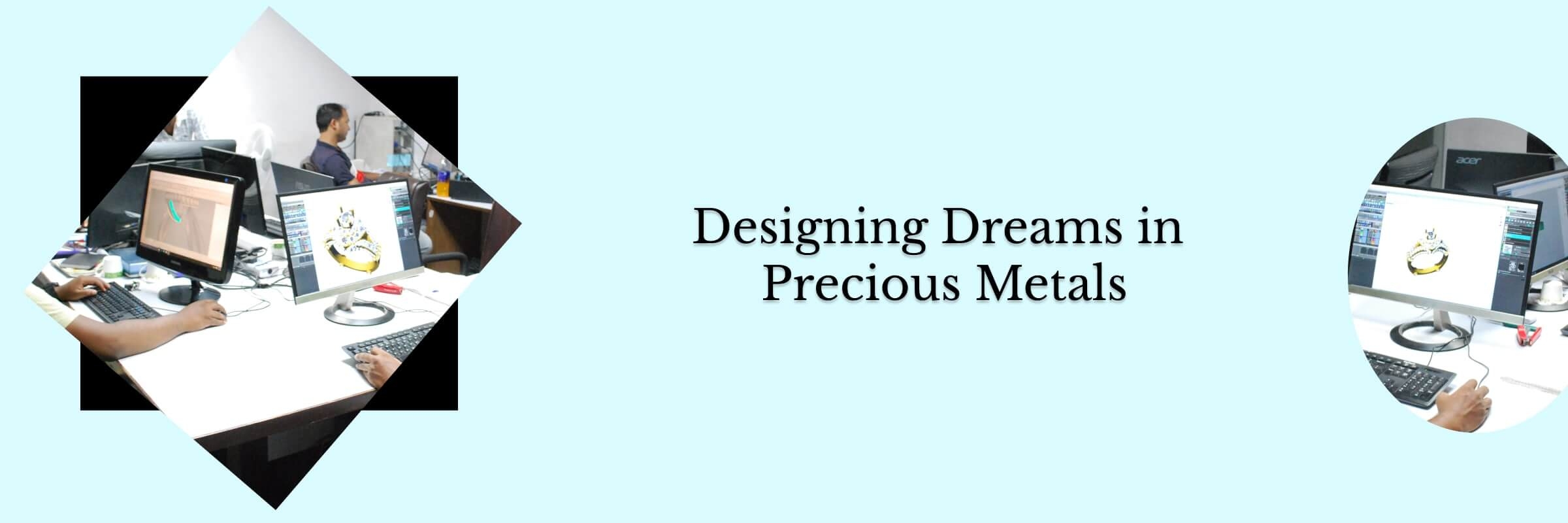

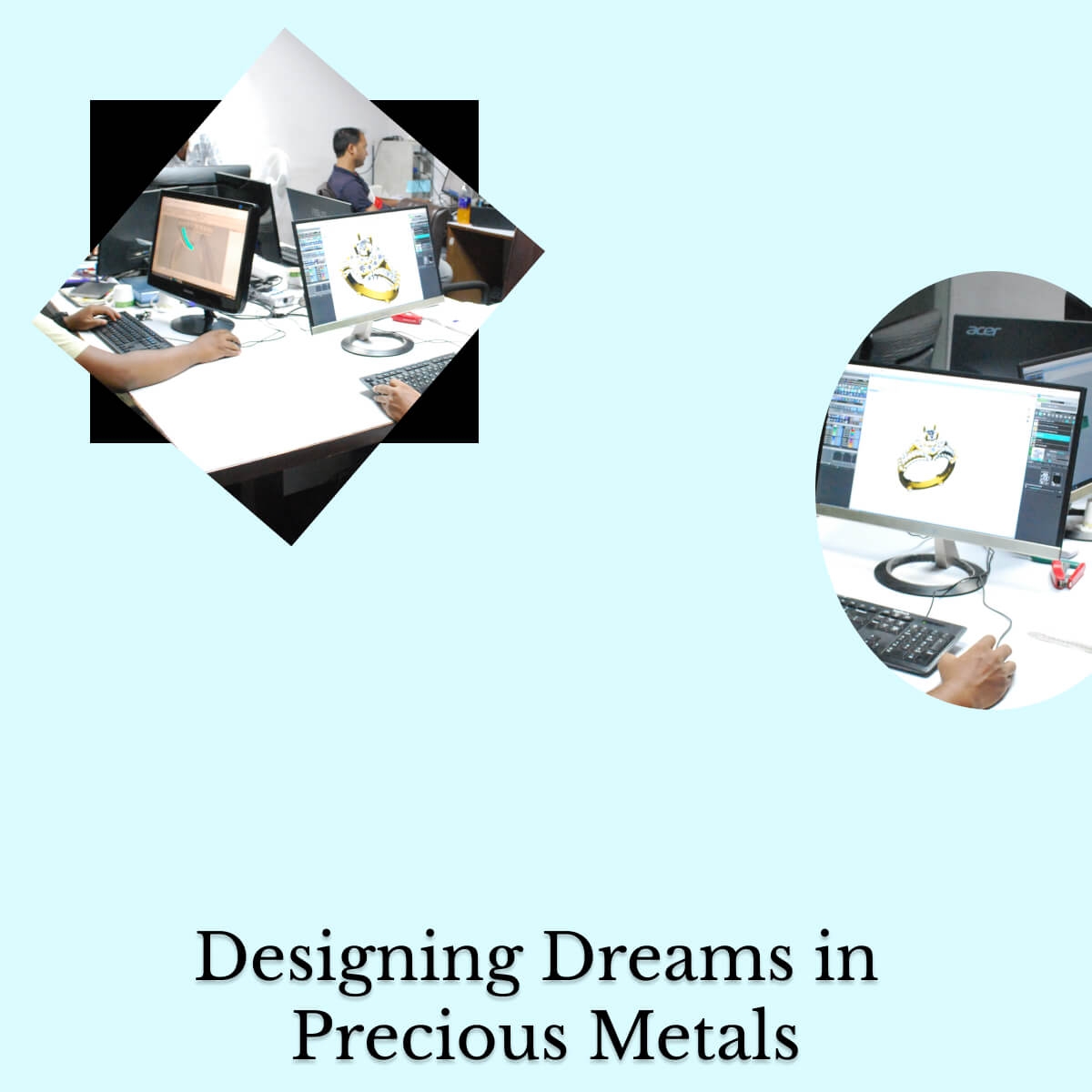

The caming process begins with a flash of innovativeness. For Wholesale Gemstone Jewelry Manufacturers and Suppliers, the initial step is imagining a piece of jewelry. This vision is then rejuvenated through computer-aided design (CAD) software. CAD designing considers exact and complex designs, guaranteeing that everything is represented. It is here that designers lay out the establishment for the entire jewelry production process, making plans that guide the craftsmen in their art.

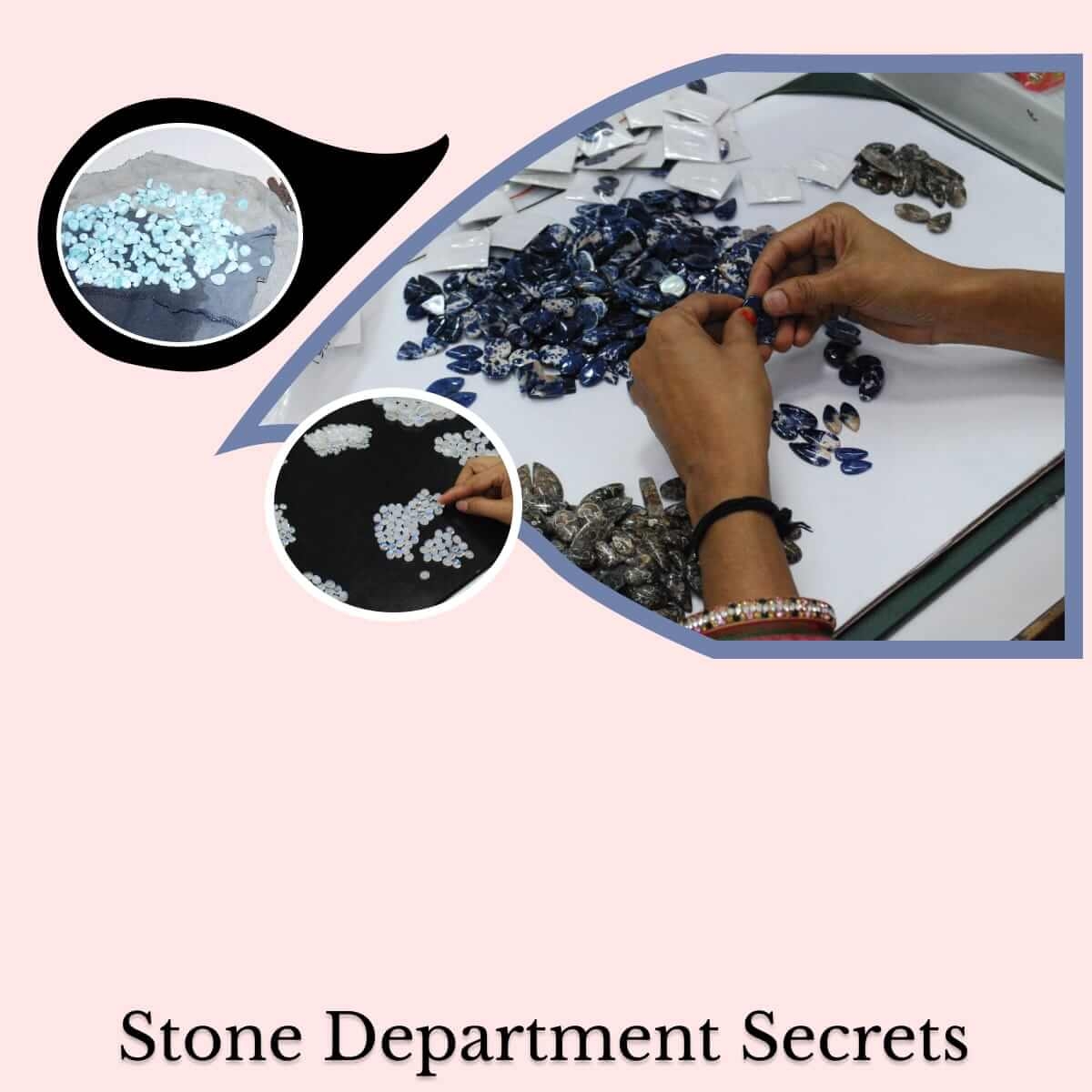

Raw Materials: Gemstone Selection and Stone Department

One of the key components that make gemstone jewelry genuinely extraordinary is the selection of gemstones themselves. Gemstone selection is a fastidious process where specialists evaluate the quality, variety, cut, and clarity of each stone. The Stone Department assumes an imperative part in this process, guaranteeing that only the best gemstones advance into the jewelry pieces. Whether it's the charm of sapphires, the splendor of opals, or the extravagance of moonstones, the decision of gemstone can characterize the nature of a piece.

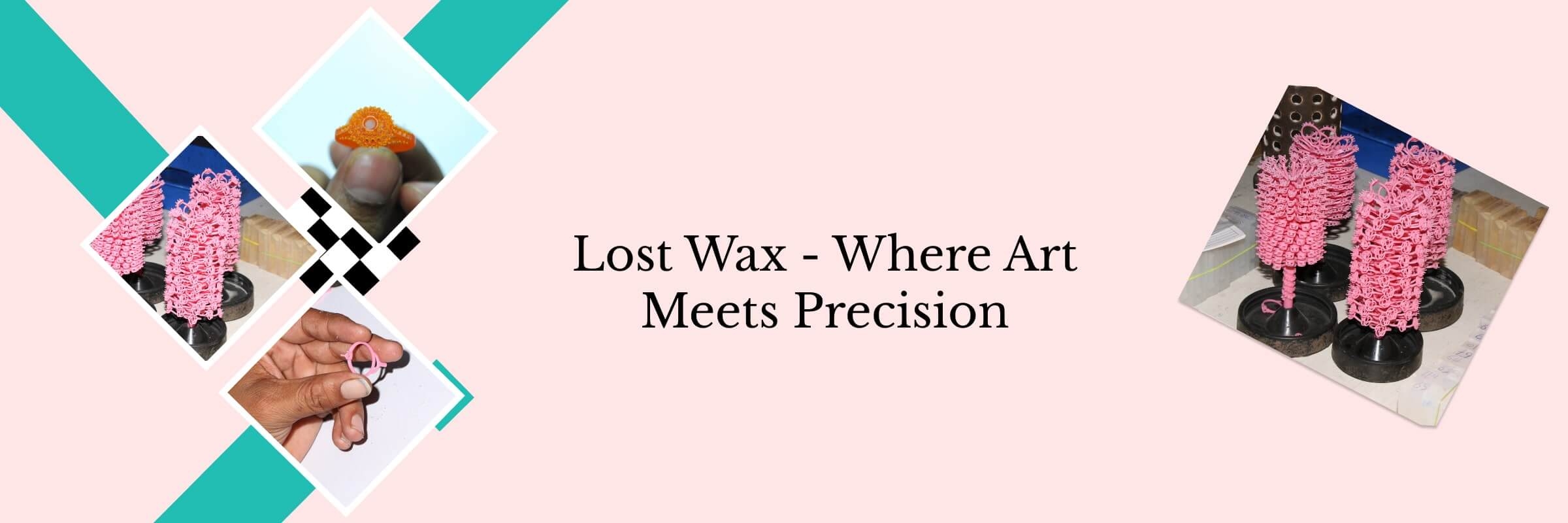

Precision Craftsmanship: The Lost Wax Process

The core of the caming process lies in the Lost Wax Process. This old procedure includes making a wax model of the jewelry piece, complete with perplexing details. The wax model is then encased in a shape and warmed, making the wax melt away and leaving behind a cavity that perfectly mirrors the design. This cavity is then filled up with molten metal, bringing about an imitation of the original wax model. The Lost Wax Process is where accuracy craftsmanship becomes the immense focus, guaranteeing that each bend and shape is beautifully recreated in metal.

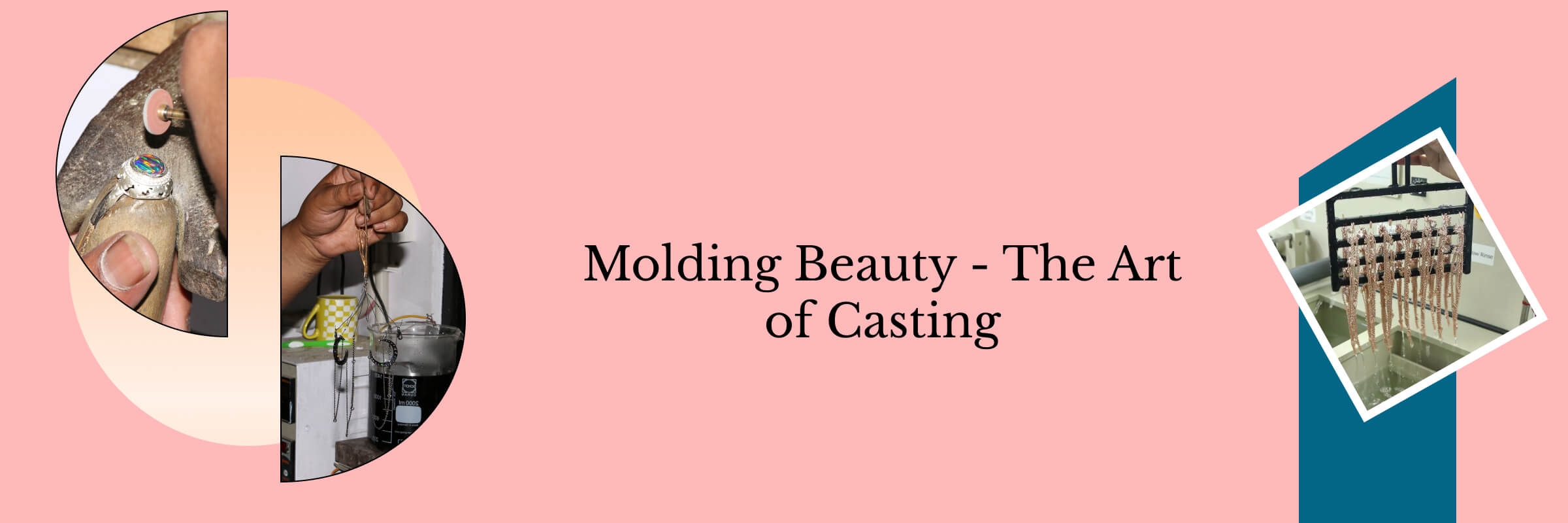

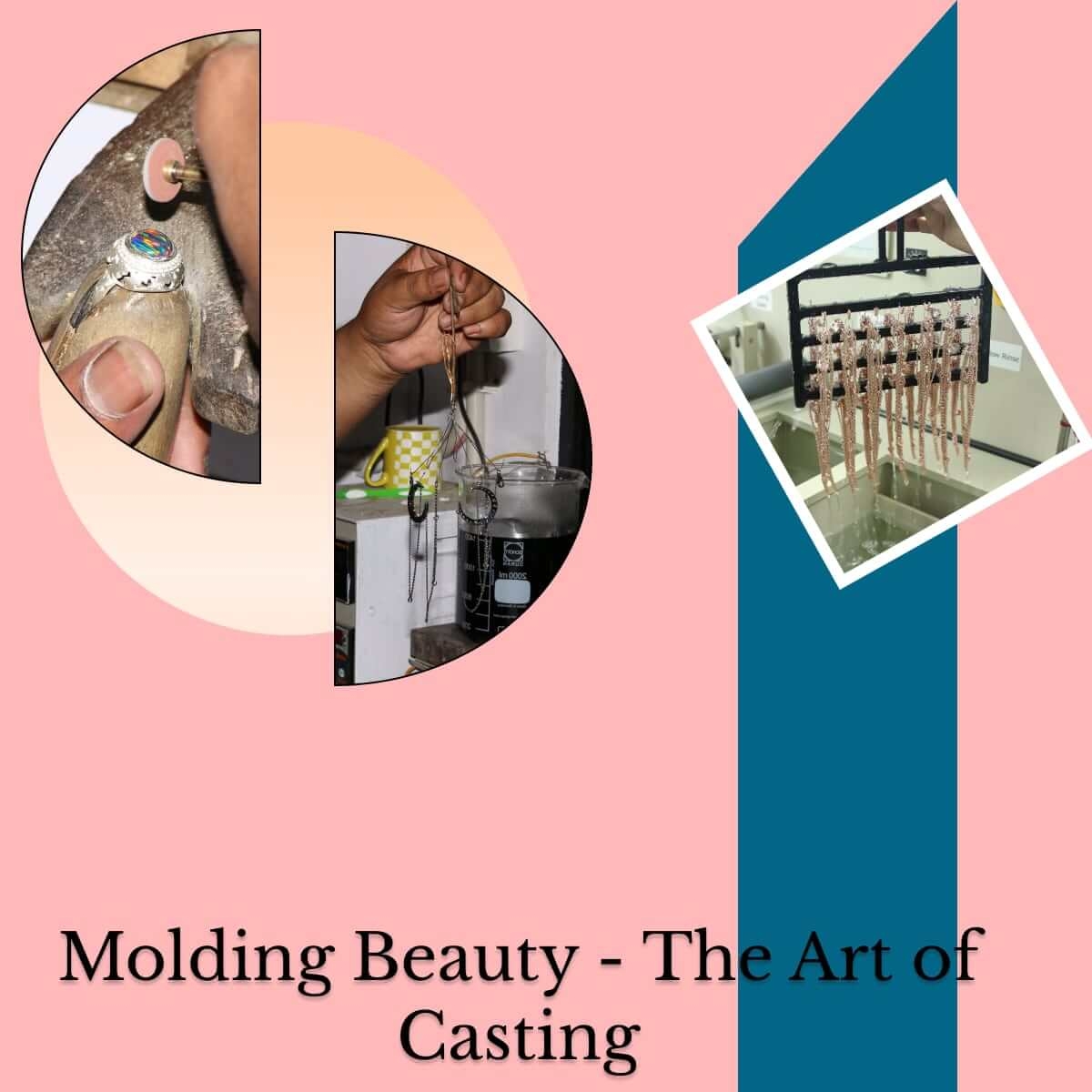

Casting Magic: Casting Jewelry

When the metal is filled into the mold, it sets to frame the jewelry piece. This step, known as casting, is where the magic occurs. Wholesale Gemstone Jewelry Manufacturers and Suppliers utilize different metals like rose gold, 925 Sterling silver, plain silver, platinum, and more, depending upon the design and client preferences. Casting changes the abstract design into a substantial piece of jewelry, fit to be refined and embellished with gemstones.

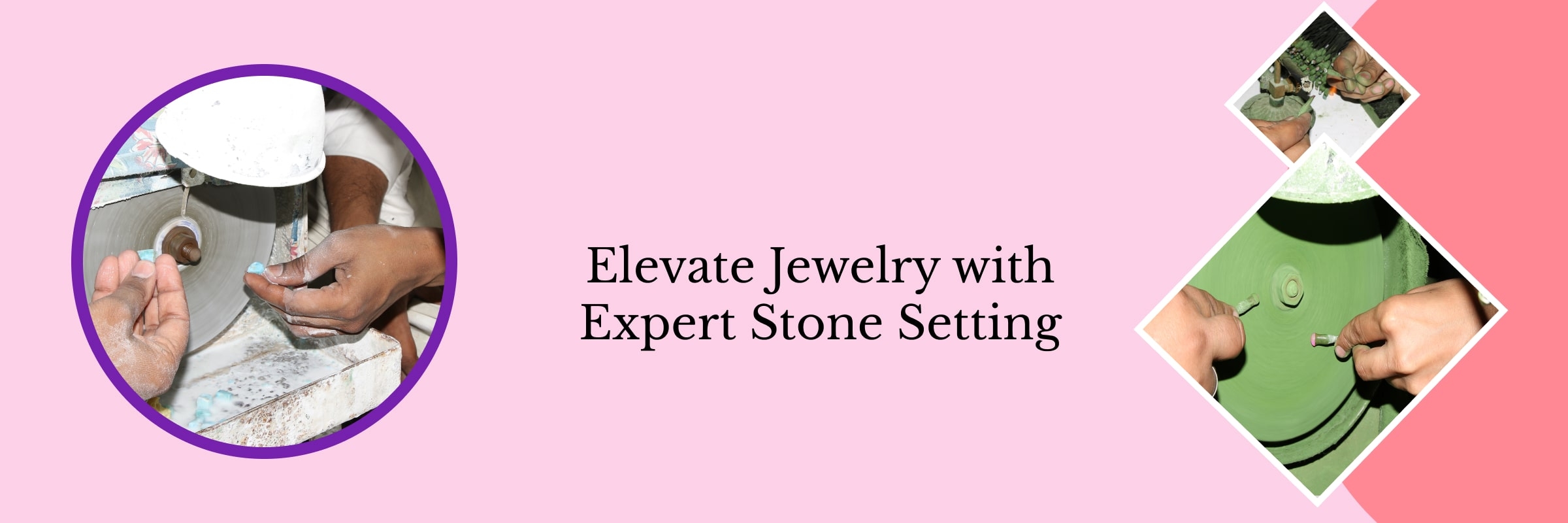

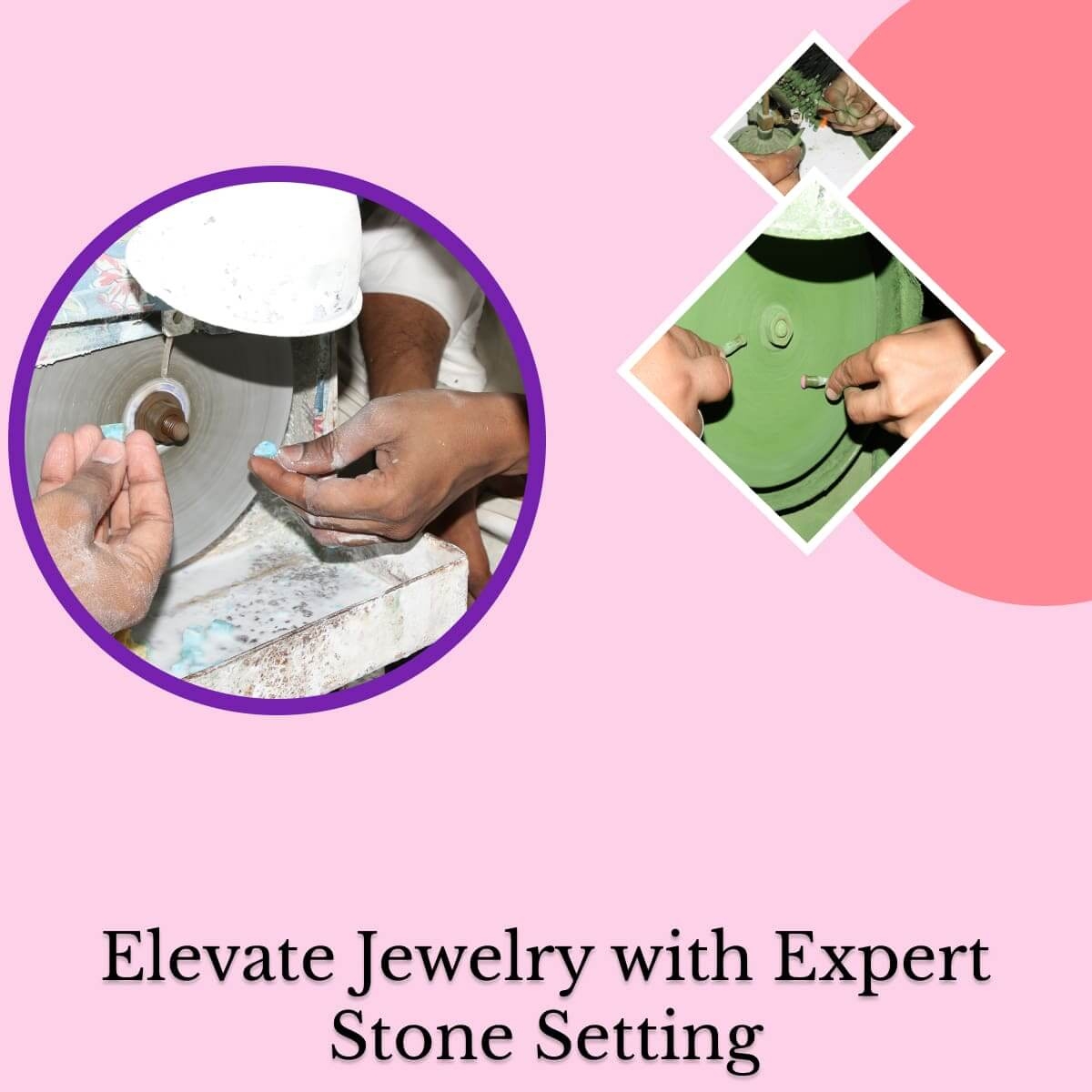

Setting the Stage: Stone Setting

Stone setting is a fragile craftsmanship that requires remarkable expertise and accuracy. It is the process of safely placing gemstones into the metal setting of the jewelry. The Stone Setting department is accountable for carefully adjusting every gemstone, guaranteeing that it fits perfectly as well as shines brilliantly. Different techniques like prong, bezel, channel, and pave settings are used to make various styles and effects. Stone setting can lift a piece from beautiful to stunning.

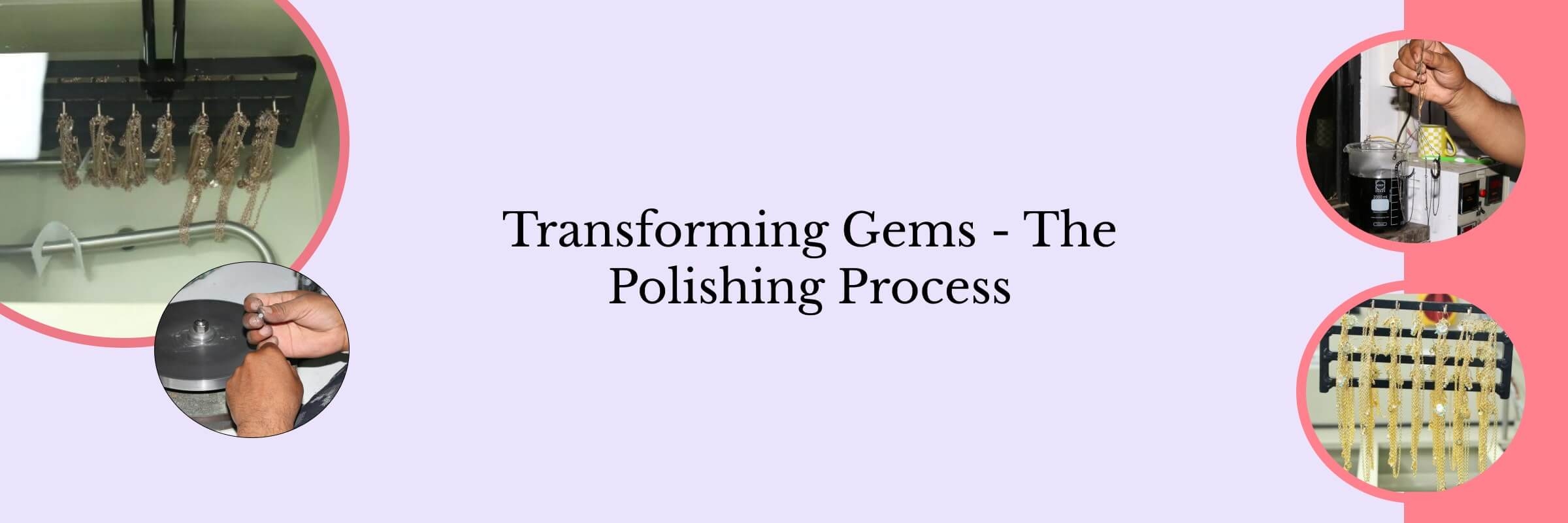

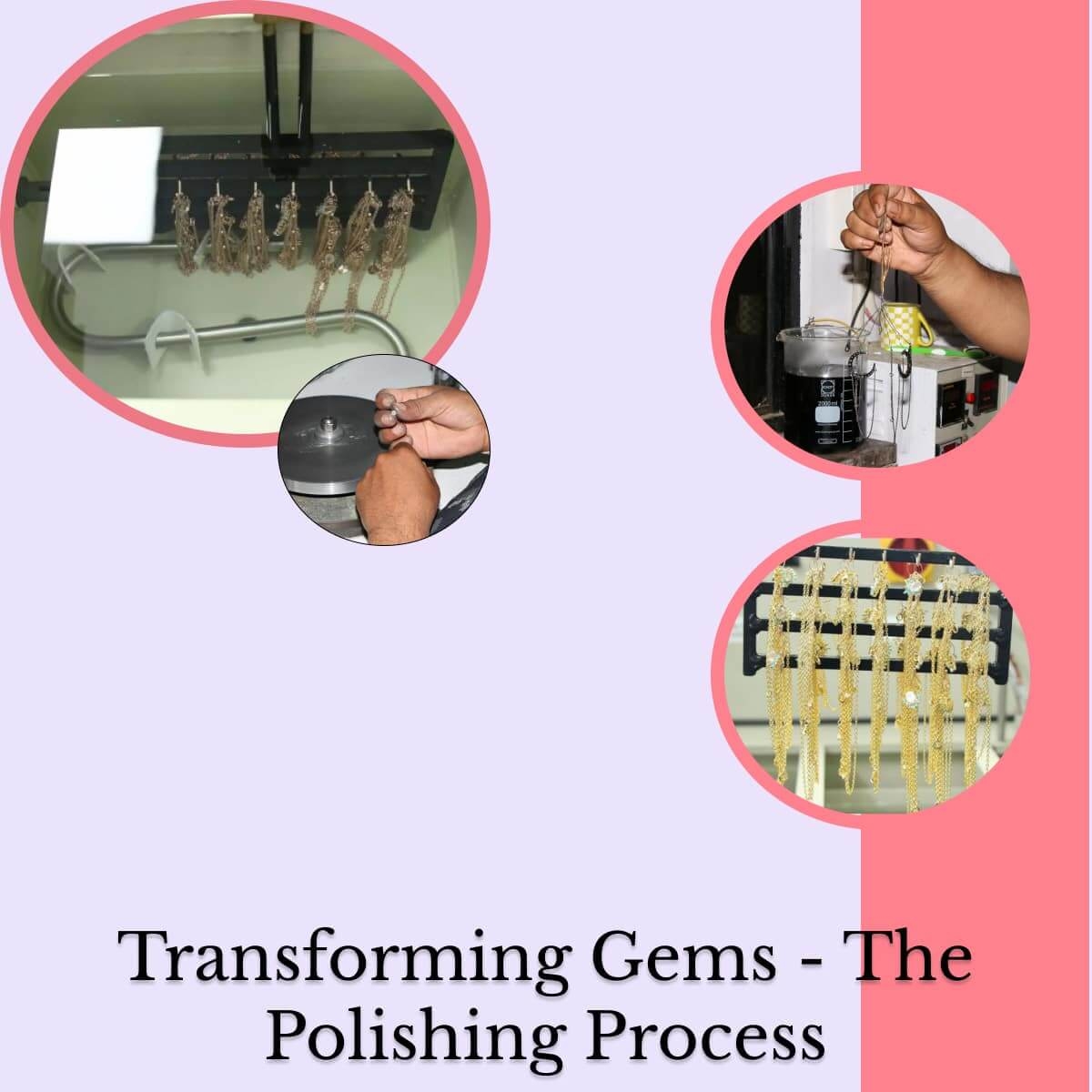

Adding Sparkle: Gemstone Polishing

To open the maximum abilities of gemstone jewelry, the gemstones should be polished flawlessly. Gemstone polishing includes molding, shaping, and cutting the gemstones to uncover their natural magnificence and brightness. Each sort of gemstone requires an extraordinary approach because of variations in hardness and quality. Whether it's the red-hot shimmer of garnet, the glossy sparkle of an agate, or the brilliant gleam of a lapis, gemstone polishing is the last step toward enhancing their charm.

The Finishing Touch: Jewelry Plating

Jewelry plating is the final detail that adds a layer of sparkle and protection to the jewelry piece. Plating includes applying a dainty layer of valuable metal, like gold or rhodium, onto the outer layer of the jewelry. This upgrades the appearance as well as gives a defensive layer against discoloring and wear. Plating choices vary, and Wholesale Gemstone Jewelry Manufacturers and Suppliers can take special care of various client preferences, from exemplary gold to contemporary rose gold or white gold.

Ensuring Perfection: Jewelry Quality Check

Quality is non-debatable in the realm of jewelry. Before a piece is considered prepared and available to be purchased, it goes through rigorous quality checks. These checks envelop all that, from evaluating the gemstone quality and setting security to plating uprightness and overall craftsmanship.

Beyond the Basics: Custom and Designer Jewelry

While the caming process gives a standard system to jewelry manufacturing, it also offers the adaptability to make custom and designer jewelry. Custom jewelry takes special care of the unique preferences and choices of individual clients. It permits them to rejuvenate their dreams, whether it's a custom engagement ring or a personalized pendant. Designer jewelry, on the other hand, includes collaborating with eminent designers to make elite collections that mirror their artistic flair.

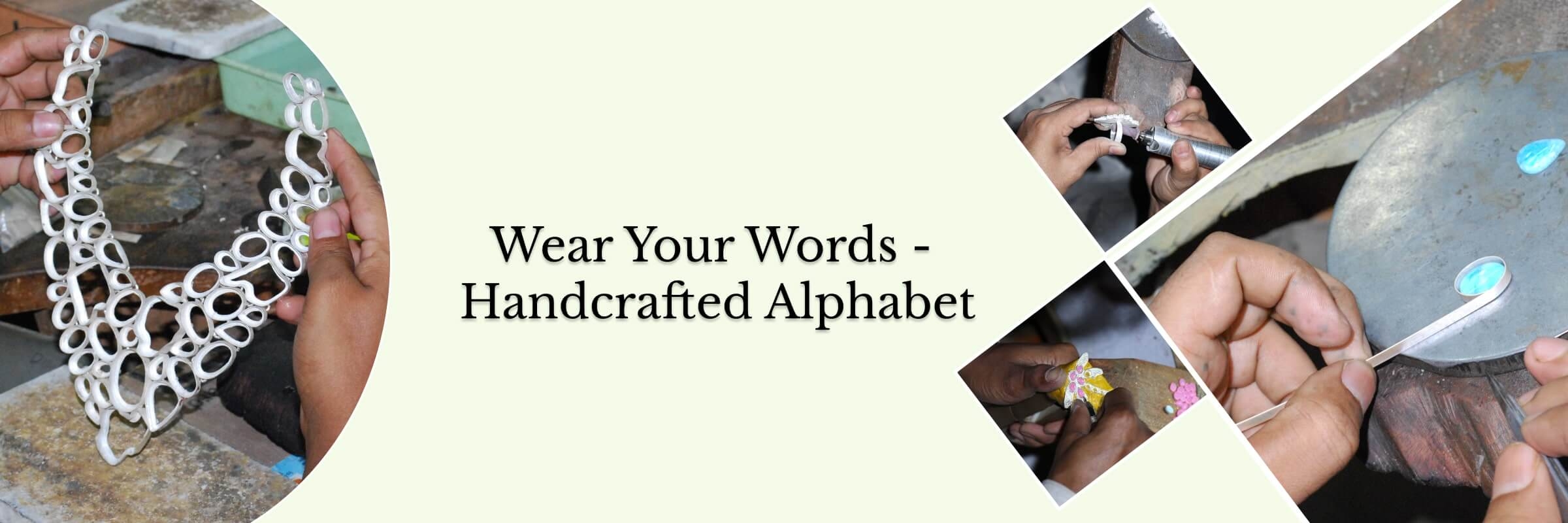

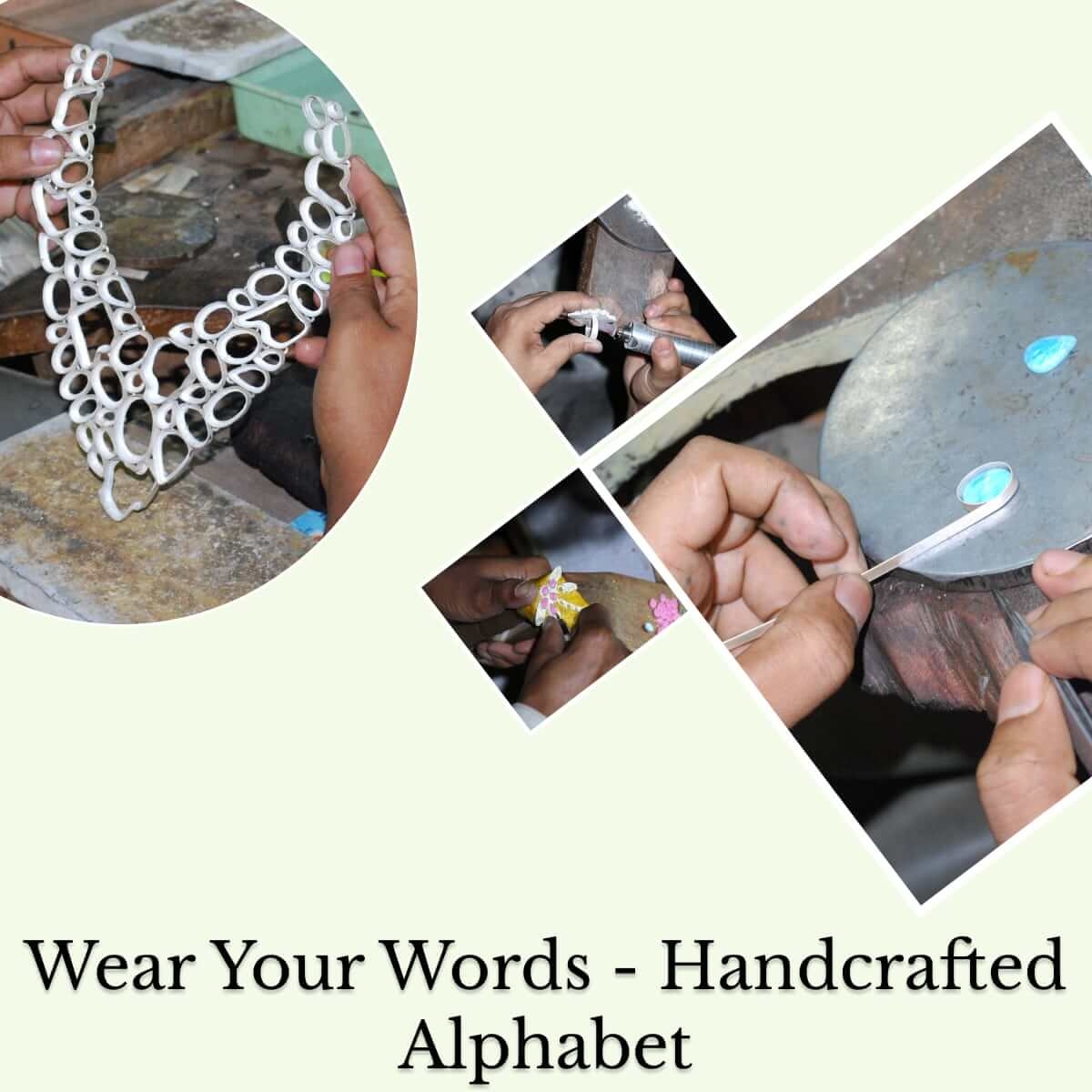

Crafting with a Personal Touch: Handmade and Alphabet Jewelry

The caming process likewise takes care of customization and personalization, offering clients the chance to make exceptional and unique pieces. Whether it's creating alphabet jewelry to illuminate a name or designing a custom piece that holds sentimental value, the caming process can bring these visions to life.

In a period where large-scale manufacturing overwhelms, handmade jewelry remains a demonstration of genuine craftsmanship. The caming process embraces these practices, permitting craftsmen to mix their mastery, energy, and innovativeness into each piece.

The Business Side: ODM and OEM Jewelry Manufacturing

As well as taking special care of individual clients, Wholesale Gemstone Jewelry Manufacturers and Suppliers frequently participate in ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) processes. ODM Jewelry Manufacturer includes delivering jewelry in view of pre-planned ideas and offering them to retailers or wholesalers. Then again, OEM Jewelry Manufacturer includes delivering jewelry as indicated by the determinations and marking of a client, who then markets and sells the items under their own name.

These parts of jewelry production add to the business' different ecosystem. Whether you're an original equipment manufacturer (OEM) seeking to brand your jewelry line or an original design manufacturer (ODM) in need of a trusted partner to bring your creations to life, the caming process is flexible enough to accommodate both.

Final Thought

The caming process fills in as the foundation of gemstone jewelry creation. It changes unrefined substances into perfect pieces that get the heavenliness of gemstones and the craftsmanship of craftsmen. From wholesale gemstone jewelry manufacturers to individual designers, this cycle is principal in making jewelry that retells a story, conveys nostalgic worth, and stands as a testament to the human creative mind and skill. Whether you search for custom designs, handcrafted pieces, or complex gemstone settings, the caming process is the best approach to opening the world of astonishing jewelry.

As Wholesale Gemstone Jewelry Manufacturers and Suppliers proceed to develop and adjust to evolving patterns, the world of jewelry manufacturing remains a dynamic and consistently developing industry. With a blend of custom, development, and creativity, the caming process ensures that gemstone jewelry continues to enamor and adorn the ages to come.