This website uses cookies to ensure you get the best experience on our website. Read more

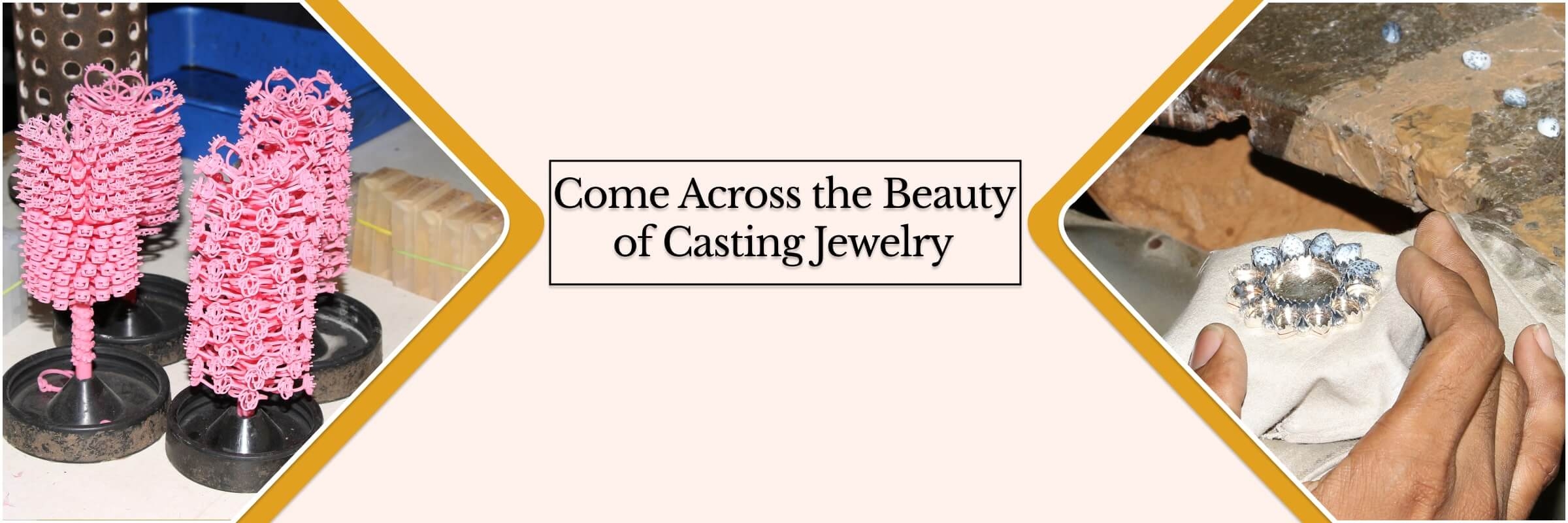

Discovering The Beauty of Casting Jewelry

What Is Casting Jewelry?

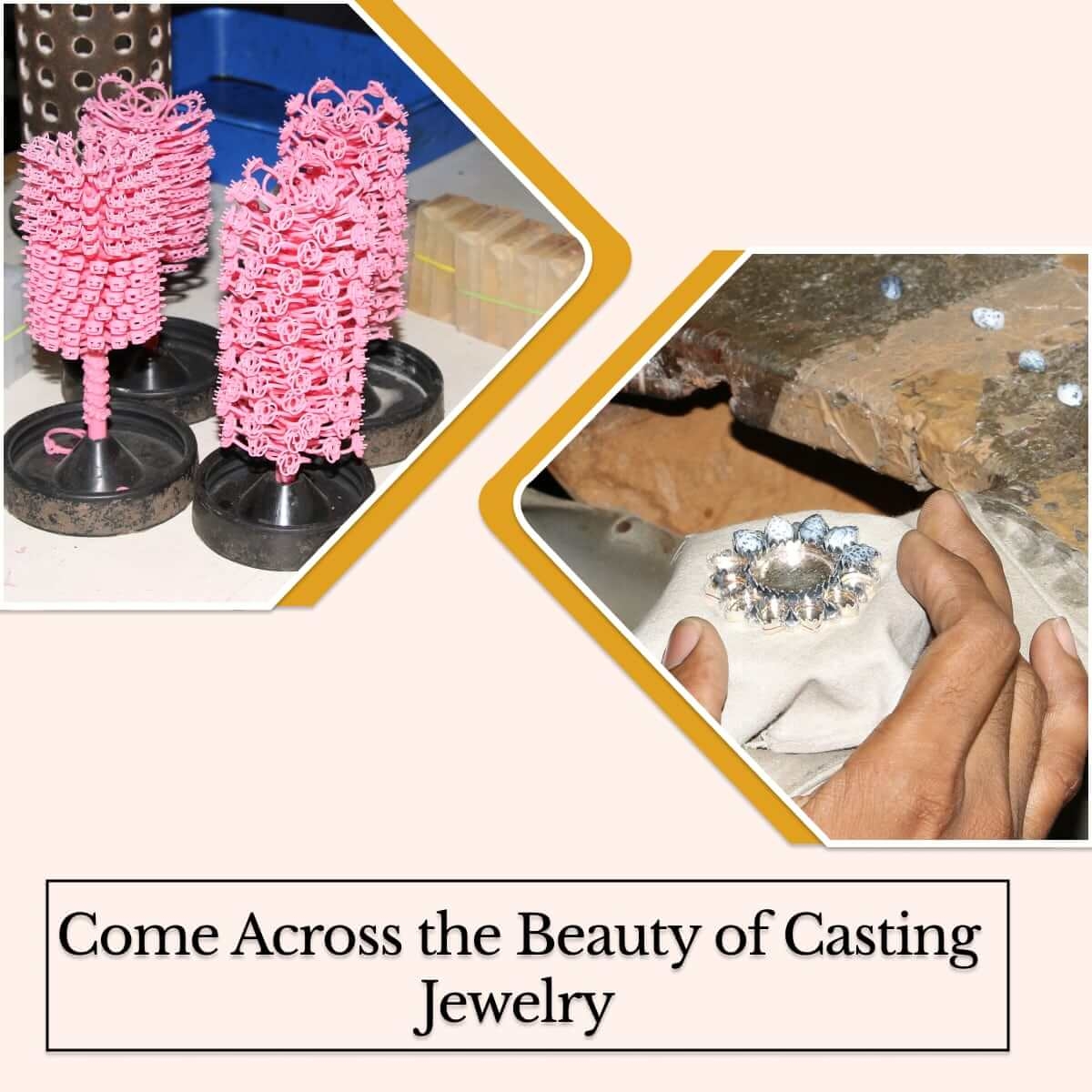

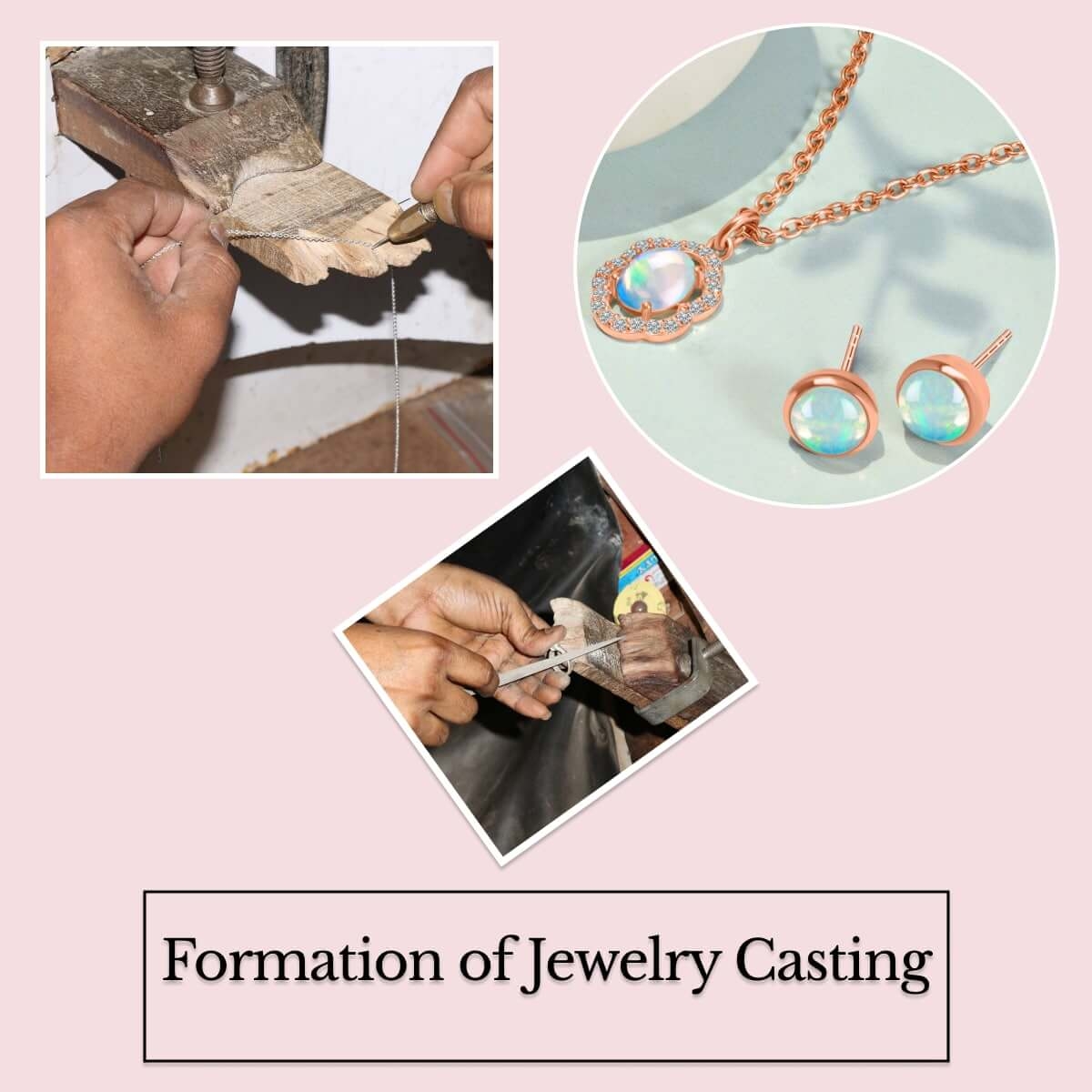

Casting jewelry is an ancient technique for creating beautiful jewelry. Molten metal is poured into a mold to manufacture jewelry via casting, which results in objects with flawless symmetry and intricacy. A furnace is used to melt the metal, which is then poured into a mold designed to hold the final metal product and cooled until it hardens. You can make one-of-a-kind jewelry items using casting that isn't available anywhere else. Designer Jewelry, Handmade Jewelry, Chakra Jewelry, Birthstone Jewelry, Zodiac Sign Jewelry, Alphabet Jewelry, and Plain Silver Jewelry are just a few of the attractive jewelry pieces created using the jewelry casting technique.

The casting method enables designers to accurately produce complex and elaborate designs. Different metals could be used to cast the jewelry. Another popular option is 925 Sterling Silver. In order to produce genuinely unique pieces, they can also mix colors and pour various metals together. Casting jewelry is a time-honored, exacting art that offers countless creative possibilities.

"For thousands of years, people have been creating jewelry by casting metal into various shapes. Molten gold has been poured into cavities made in cuttlefish bone, plaster, stone, and other materials since men first developed the capacity to melt metal. The solidified castings were first pryed, or broken, free from the encasements into which they were poured, and were then tooled into ornamental pieces by primitive artisans. The majority of jewelers work is done using the lost wax technique, which involves encasing wax carving and growing that have been produced through models or printing in a material that resembles plaster. In order to burn the material and imprint it with the appropriate form, extreme heating is an expenditure.

Molten precious metal is then filled by an intricate cavity. Including the gold casting, platinum casting, and 925 Sterling Silver casting, there are significant differences between the various casting processors. Metals are heated to their molten state for casting since each metal has a different melting point.

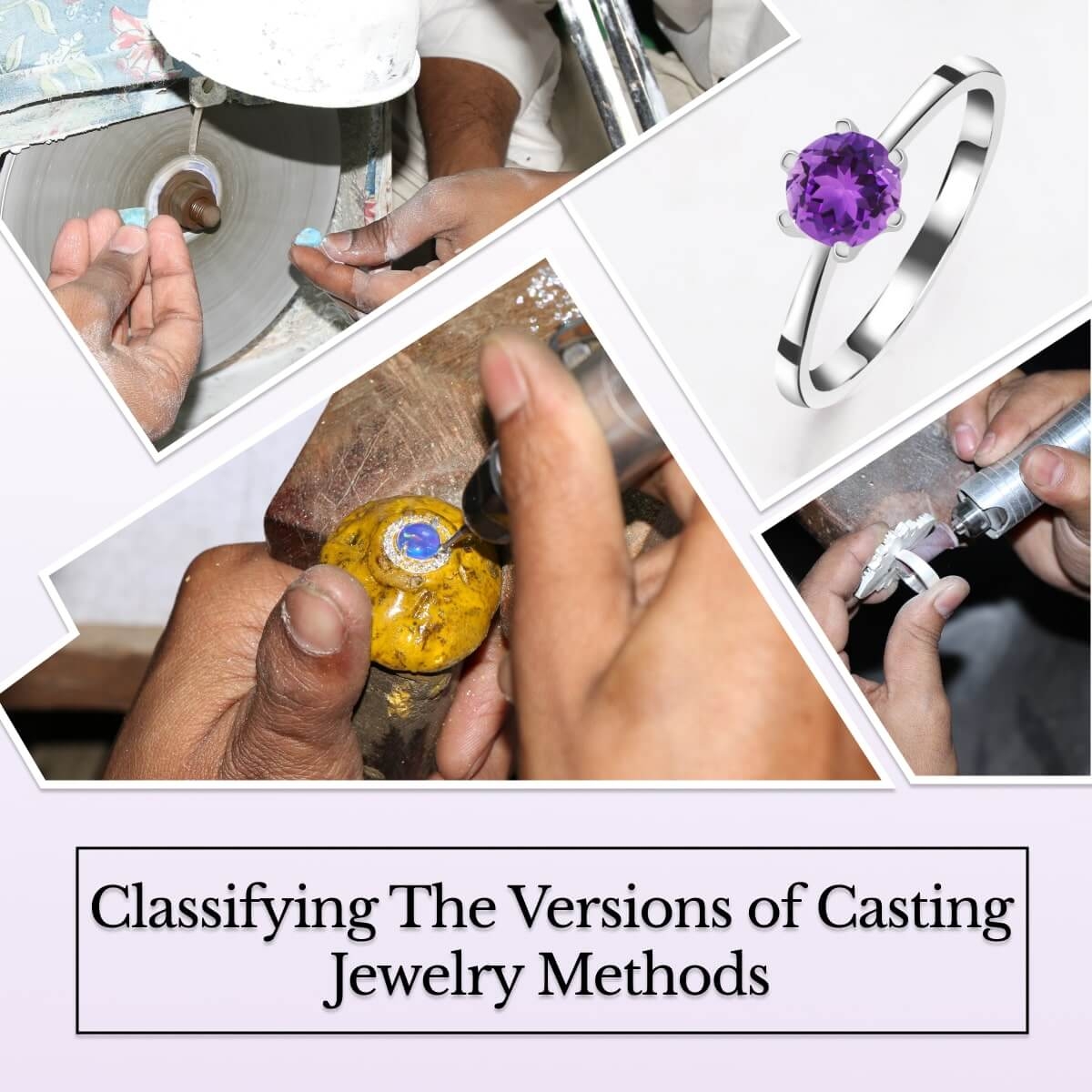

Different Types Of Jewelry Casting Methods

"Sand casting and lost casting" are two of the casting methods that are used to make jewelry. Creating a metal sculpture to serve as a mold for a material, such as plastic or sand, is the procedure known as "sand casting," which was mostly utilized in antiquity. Wax models are submerged in liquid plaster or clay before being poured over by molten metal to create the desired shape.

Jewelry-making processes that use lost wax casting are more often used. Both methods need and develop a lot of talent and experience, and attention to detail, precision, and success are crucial for good outcomes. Either process will result in jewelry with elaborate and thorough craftsmanship, making it possible to create truly unique pieces.

Lost-wax casting, cuttlefish bone casting, and investment casting were the three basic methods of jewelry casting. Because each type of Jewelry Casting is unique, the advantages vary depending on the level and type of design detail needed. With lost casting, a designer makes a wax model, then coats the cavity of the mold with plastic. Cuttlefish bone casting substitutes a porous bone for the wax in place of investment molding, which employs a ceramic compound that solidifies around the wax model before melting it away. Jewelry producers frequently use lost wax casting to create intricate and detailed pieces. The design is created as a wax model, which is then used to mold the plaster and heated until the wax melts away, creating a cavity into which the metal is subsequently poured.

This method requires a lot of labor and work. Although it requires a lot of labor, the outcomes are amazing. This method provides precise and clear designs and is utilized in the casting of jewelry with complicated motifs. Unlike the lost wax method, which melts the liquid metal away, cuttlefish bone casting uses a porous bone that absorbs it. Many people like this kind of casting since it takes fewer steps and less time than other techniques.

The designer's wax model is encased in a mould and then melted away in the investment casting process to produce an even more accurate cast. This method as compared to the cuttlefish bone or lost-wax casting takes a longer time but it provides great accuracy which is why it is quite preferred. This method works well for producing Designer Jewelry as it gives accuracy and perfect details.

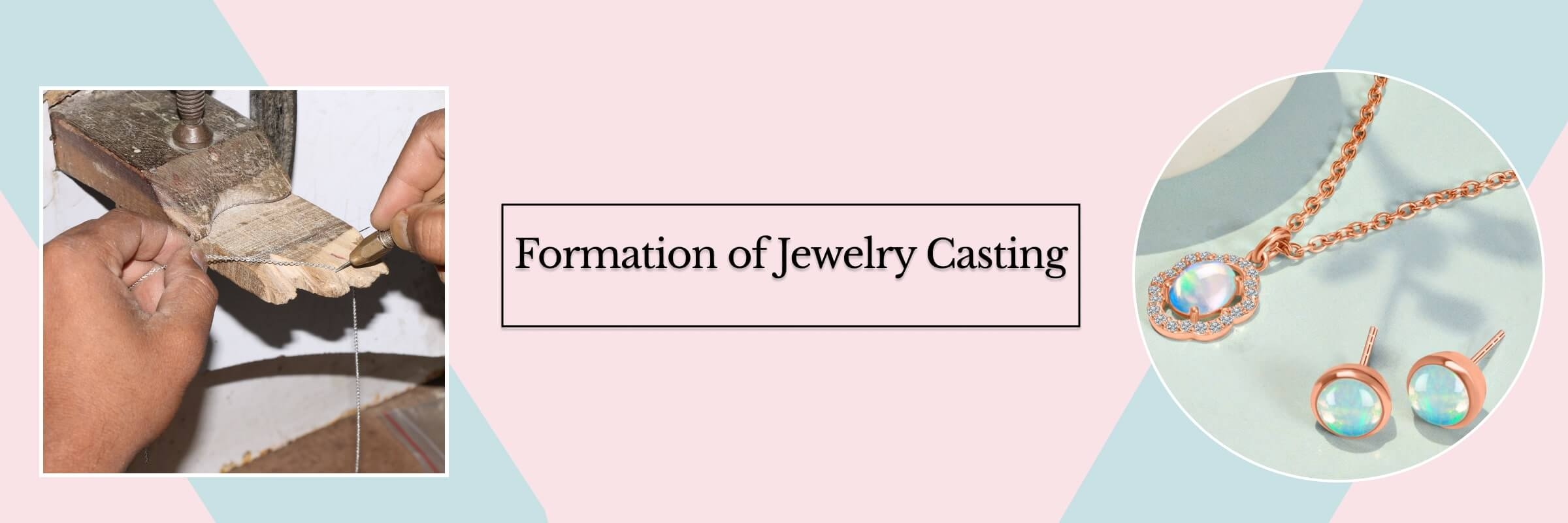

Jewelry Casting Process

Numerous phases are involved in the Casting Jewelry, which gives the procedure a complicated appearance. First, a mold is made, then molten metal alloy—typically a gold-copper alloy—is poured into the mold. One-piece molds and two-piece molds are two different types of molds. To make the ideal cast, a variety of equipment and materials are required depending on the type of mold utilized. For melting metal alloys, common equipment includes steel ladles, non-ferrous crucibles, jigs, and tongs for inserting molds into mould formers.

Additionally, flasks would be required for compacting sand around the molds and iron around cores shaped like tree trunks to create hollow items. Sprue cutters that resemble carpenters compasses would be needed to remove superfluous metal from casting surfaces, as well as pouring buckets made of bronze, brass, or plastic sheeting and pouring buckets that mimic regular buckets found on construction sites. The process of Casting jewelry results in the formation of Custom Jewelry, Chakra Jewelry, Birthstone Jewelry, Zodiac Sign Jewelry and Alphabet Jewelry.

Jewelry Casting Service

Different kinds of metals, such as gold, silver, bronze, and brass, are utilized in the casting process for jewelry. The different metals have varied qualities that have an impact on how casting would proceed when that particular metal is present. Discovering a reliable Jewelry Casting Supplier is the first step. The greatest option would be to select a service provider with expertise in this area who can advise you on appropriate tools and methods. For casting, many molds are available, including sand molds and investment molds. Choose thoughtfully based on the needs of your project because each type has benefits and drawbacks.

When it comes to jewelry casting services, there are several possibilities. There are several providers offering the best quality assurance. While some jewelers outsource the task to specialized casting firms, others provide in-house casting services. Choosing the best jewelry casting service might be challenging. When selecting a Casting Jewelry Supplier, there are a few things to keep in mind. It's crucial to take into account aspects like cost, quality, response time, and customer service when selecting a service provider. The capacity to manufacture personalised jewelry pieces and a range of other sorts, such as Designer Jewelry, Handmade Jewelry, Chakra Jewelry, Birthstone Jewelry, Plain Jewelry, Zodiac Sign Jewelry, And Alphabet Jewelry, is one advantage of employing a professional jewelry casting service.

Where To Buy The Best Casting Jewelry ?

Jewelry Casting is not a novel technique; it has been used for thousands of years. Now that you are knowledgeable with jewelry casting, its methods, and its various varieties. You must have some cast jewelry and custom jewelry in your collection. When it comes to casting jewelry, there are several alternatives. You could pick from enticing Birthstone Jewelry, Chakra Jewelry, or Handmade Jewelry. Given that it is among the most reputable Wholesale Gemstone Jewelry Manufacturers & Suppliers, Rananjay Exports is the best option. More than 5000 satisfied clients have used our company, and we would love to work with you.